MECHANICAL SEALS

Prevent environmental contamination, save energy with greater efficiency, and increase machine safety with mechanical seals.

TYPES OF MECHANICAL SEALS

TO FIT YOUR APPLICATION

Mechanical seals are sealing solutions for any machine that has a rotating shaft, like pumps or compressors. Mechanical seals are a kind of packing that is installed on the power transmitting shaft of a rotating machine. Without a seal or with just gland packing, the liquid will leak and the axis will wear. With a mechanical seal, leaks are minimized and the axis does not wear. This is because the separate rings of the mechanical seal allow for a precise and custom design to fit around the axis but not affect the rotating force of the shaft. Mechanical seals prevent leaking even with hazardous substances or under high pressure or high rotating speed.

Most mechanical seals are composed of two rings, a rotary ring installed on the shaft and a stationary ring installed on the pump housing. The rotary ring rotates with the shaft, and the two rings rub against each other, ensuring clearance of micrometers between them.

BENEFITS OF

MECHANICAL SEALS

Mechanical seals have a number of benefits for applications that require the prevention of contaminants during the use of rotating machines.

- No “visible leak.” While the seals do leak as vapor, the amount leaked is approximately ½ teaspoon a day at normal operating temperatures and pressures

- Modern designs prevent damage to the pump shaft or sleeve

- Daily maintenance is reduced as seals have inboard springs which allow them to self-adjust as the faces wear

- Seals have lightly loaded faces which consume less power than gland packing

- Contamination is reduced in normal operation as the lubricant is not affected by seal leakage and wash out

- Plant equipment suffers less corrosion, as the product is contained in the pump

- Vacuum sealing is possible with this technology, as air is not drawn into the pump

- Less wasted product means more money saved

- Less clean up around the area makes the surrounding environment safer

INDUSTRIAL USES FOR

MECHANICAL SEALS

Mechanical seal manufacturers serve a variety of industries, such as:

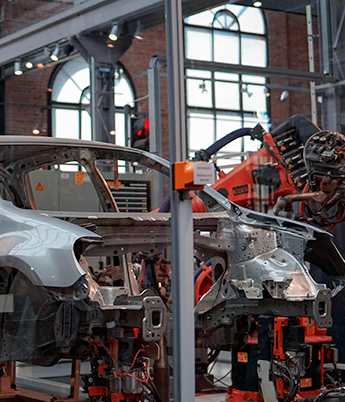

- Automobile

- Ships and marine

- Rockets and aerospace

- Industrial plant equipment

- Residential devices

- Any industry that moves liquid or uses rotating machines

NW INDUSTRIAL SALES, LLC IS YOUR

SEALING SOLUTIONS DISTRIBUTOR

NW Industrial Sales, LLC is a leading fluid sealing solutions distributor offering a variety of fluid sealing products. We have a combined 75 years of experience working in industries as diverse as pulp and paper, gain, and marine.

As certified agents for Rexnord’s Industrial Services Division, you gain access to their nationwide maintenance network. We have an extensive inventory of parts and many different types of mechanical seals perfect for your application.

We are here 24/7 to help you find the right solution for your industrial application. Contact us today.