FALK GEARBOX RESOURCE GUIDE:

EVERYTHING YOU NEED TO KNOW

With over 75 years of combined experience helping industrial businesses with their gearbox needs, we pride ourselves on providing our supporters with comprehensive resources on Falk services and products.

Here you will find an extensive assortment of resources and detailed insights about Falk gearboxes, all meticulously curated by our specialists. This collection is designed to cater to your informational needs and enhance your understanding, ensuring you have access to the most reliable and up-to-date knowledge available.

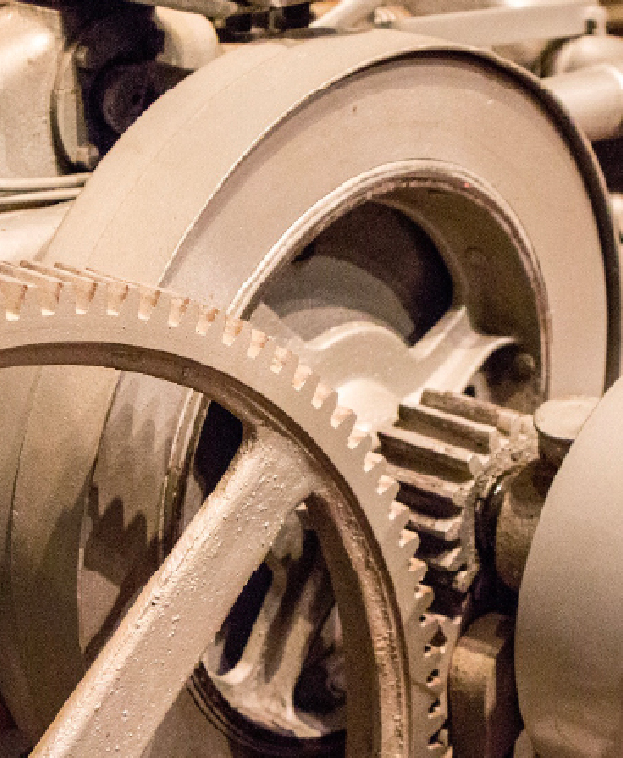

WHAT ARE GEARBOXES

Gearboxes are mechanical devices that transmit power and torque from one rotating shaft to an endpoint like a motor. They are designed in various configurations to meet the needs of countless heavy-duty applications in a variety of industries.

It’s worth noting that when referring to a gearbox, you might encounter terms like speed reducer, gear drive, or gear reducer, but they all refer to the same component and can be used interchangeably.

The primary purpose of a gearbox is to increase output torque or change speed. A gearbox does this by transferring power in a rotary or linear motion, allowing the machine to decrease or increase the torque and speed based on the application. This empowers industries such as mining, oil and gas, pulp and paper, and others to adjust the speed and torque according to specific operational requirements.

The Key Components of an Industrial Gearbox

- Input Shaft: Also referred to as a clutch shaft, this component transmits power from the clutch disk to the transmission.

- Countershaft: This component is a rod with helical gears that transfers power from the input shaft drive gear to the output shaft from the clutch shaft to the main shaft.

- Main Shaft: Comprising two gears that engage with splines on the shaft, with one serving as the first and reverse gear and the other as the second and third gear.

- Housing: This protective casing is designed around a specific application and protects the unit.

- Gears: Gearing transmits power between different motor shafts.

- Bearings: These support the rotation shafts in a motor, securing the shaft to ensure efficiency.

- Seals: Seals maintain the oil in a gearbox while protecting the machinery from dirt, grime, and other pollutants.

Gearboxes are essential to manufacturing because they can optimize a motor’s performance while increasing precision. They do this by adjusting the torque, speed, and direction between the shaft and the engine to produce the chosen result or operational output.

THE HISTORY OF MODERN GEARBOXES

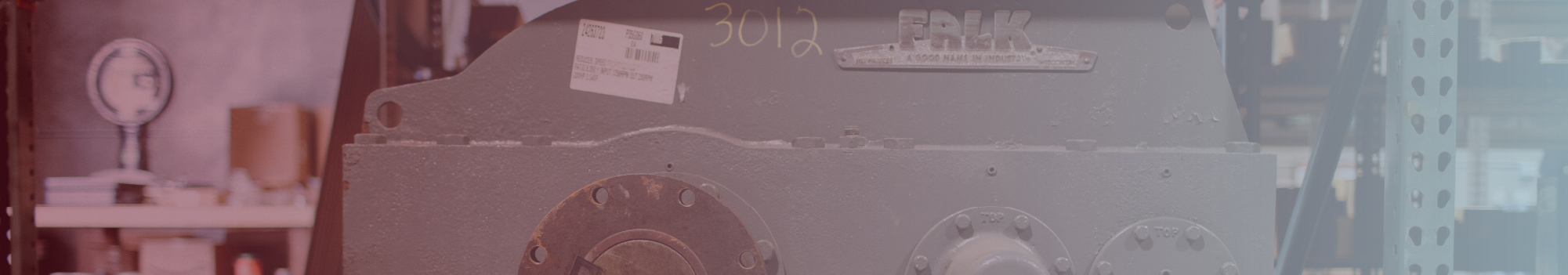

Herman Falk started the Falk Corporation in Milwaukee, Wisconsin, in 1892. Falk first produced wagon couplings and later electric street railway supplies before creating high-quality gears that replaced the belt drives of the 19th century.

Falk’s pioneering gearboxes played a groundbreaking role in the 20th century, finding applications in diverse machinery, from World War II ships to automotive transmissions.

Purchased by the Rexnord Corporation in 2005, Falk gearboxes have maintained their legacy of excellence, still being produced today. They are renowned globally as top-of-the-line speed reducers, known for their contemporary design, reliability, and ability to withstand the most demanding industrial applications.

Modern Gearing by Falk:

- Spurs

- Helical and double helical

- Bevel

- Worm

- Epicyclic

- Rack

- Pinion

- Planetary

THE TYPES OF INDUSTRIAL GEARBOXES

Speed reducers offer adaptability and variety, making gearboxes by Falk the premier choice for most industrial uses. In many cases, deciding which one to use depends on the application and the machinery it helps power.

Concentric Gearboxes

Concentric gear systems situate the high-speed and low-speed shafts on the same horizontal and vertical plane. This design allows multiple concentric gearboxes to be arranged in a row within one industrial machine.

Parallel Gearboxes

This gear set sends power and torque through parallel shafts for more speed control or power reduction. Parallel gearboxes are often used in conveyor belts, fuel pumps, automotive parts, and other applications.

Right Angle Gearboxes

These gear reducers are referred to as right angle reducers because of their orientation—they sit at a 90-degree angle. This configuration is perfect for minimizing bending for extensive drive uses or if you need a gearbox for a smaller space.

Shaft Mount Gear Drives

This design distinguishes itself by directly mounting onto a drive shaft, eliminating the need for additional components or support structures. Instead, it can be easily attached near a reducer connected to chains and belts or a motor using an adapter or swing base.

THE BENEFITS OF FALK SURPLUS PARTS

As agents of Rexnord’s Industrial Services division and Falk surplus gearing and parts distributor, we understand the advantages their speed reducers offer to those seeking a reliable and efficient gearbox. Let’s take a look at those advantages in more detail.

Made to Last

For over a century, Falk has established a reputation as the leading authority in the gearbox industry by consistently delivering reliable gear solutions. This is because they utilize premium materials and state-of-the-art designs to cater to the requirements of challenging work environments while optimizing efficiency.

Versatile Design

Falk gearboxes provide adaptable solutions for optimizing the gear ratio and power configuration to achieve desired output speeds. Their compact design also allows them to be used in smaller spaces and diverse types of machinery.

Efficient Performance

Falk parts provide optimal torque and power to keep applications running at peak performance. A higher-efficiency rated gearbox requires less power consumption by using a smaller motor to improve productivity and efficiency.

Ease of Repair & Smaller Inventory Investment

As Falk technicians, we make it easier to avoid downtime if you need help finding obsolete parts or a reliable service provider. We also offer expert repair and renewal and an extensive inventory of spare parts to ensure your gearing continues to deliver optimal results.

Increased Sustainability

The environmental benefits of utilizing Falk gearboxes are gaining increased attention. In turn, more industrial businesses use their gearboxes to produce less waste, reduce resource consumption, decrease emissions, and improve efficiency.

Reduced Risk of Failure

The unintended consequences of gearbox failure may lead to lost revenue, supply chain issues, more expensive repairs, and other inconveniences. Gear drives are engineered to endure the most severe conditions. Nevertheless, any motorized component operating in rugged environments may require maintenance to avoid downtime.

THE INDUSTRIES THAT RELY ON FALK GEARBOXES

Gearboxes are essential for heavy-duty machinery requiring precise power and torque with more control dependably. With a cumulative experience of more than seven decades in serving diverse industries, here are some of the industrial enterprises we assist in maintaining their operational efficiency.

Pulp & Paper

This $350 billion industry uses speed reducers to process fibrous materials and recycled fiber into usable paper products. As motor suppliers, we’ve supported this industry by providing gearboxes for pulp processing machines, Fourdriniers, paper machine dryers, paper presses, and paper roll machines.

Offshore & Marine

In this sector, Falk gearboxes and high-quality fluid sealing solutions are essential for the smooth operation of reciprocating diesel engines on offshore drilling platforms, floating refineries, vessels, and stationary oil drilling platforms. What’s more, they’ve played a critical role in streamlining operations and reducing downtime.

Learn more about how we serve the offshore & marine industry >

Agriculture

Surplus gearing strengthens the agricultural industry by keeping heavy field machinery, warehouse equipment, and the supply chain in the right gear. Speed reducers are found in tractors, grain elevators, conveyors, and other agricultural machinery.

Power & Energy

The power and energy sector relies on gearboxes for electricity generation through turbines, the conversion of hydropower, electricity production from thermal energy plants, and various other methods. Additionally, these reducers are essential for various applications of renewable energy equipment solutions.

Mining

This industry demands resilient solutions with high torque to manage heavy loads and harsh environments, and gearboxes by Falk meet those needs. As a result, gearboxes can be found at virtually every mining site, from powering heavy conveyor belts to driving mining crushers and machines handling bulk materials.

Oil & Gas

Similar to the mining industry, it’s a challenge not to encounter a gearbox on a site in this sector. Falk speed reducers support the oil and gas industry by powering pump jacks, drawworks, top drives, cranes, and other equipment with clutches, breaks, belted drives, and drive shafts.

WHAT TO KNOW ABOUT FALK GEARBOX REPAIR & MAINTENANCE

When you select NW Industrial Sales, LLC for your Falk gear drive repairs, you gain access to a range of services as well as a variety of customized support.

We Offer National Support

Our customers deserve access to the highest quality parts and repair services from industry experts who know Falk best. Below are just some of the value-added upgrades our clients receive:

- Gearing systems made to original OEM specifications and seals replaced by original or better quality materials

- Gears and pinions made to AGMA 12 standard or better, depending on the application’s needs

- Chemically dipped housings to prevent future failures caused by debris in the lubricant

- And so much more

We Can Refurbish Gearboxes

Our Falk technicians offer cost-effective solutions that may provide a more affordable option than replacing a unit outright. Our gearbox renewal services include, but are not limited to:

- Rebuild systems to original OEM specifications

- Replace bearings, gears, and pinions with high-quality Tier 1 and AGMA 13 parts

- Replace seals in the gear with original or better quality, based on improvements in seal materials

- Conduct magnetic particle inspections, dynamic spin tests, and housing pressure tests

- Dip housing in chemicals to prevent future failures

- Repaint according to original Falk or customer specifications

We Offer Replacements for OEM & Hard to Find Parts

Our extensive inventories comprise a wealth of rare components, enabling knowledgeable individuals to conduct their own repairs should they prefer. We also offer a wide range of new and used components that may not be available elsewhere.

We encourage you to contact us if the part you require is not listed on our website. This enables us to search for and procure it on your behalf. We are at your service around the clock, ready to assist with your industrial part requirements.

COMMON REASONS FOR GEARBOX FAILURE

It’s important to properly maintain a gearbox and follow the manufacturer’s maintenance guidelines to avoid potential setbacks.

Here are some common repairs our technicians address for our clients, along with resources to educate readers on the subject:

5 GEARBOX MAINTENANCE TIPS CURATED FOR SUCCESS

- Visually examine your gearbox by following the inspection tips provided by our Falk technicians.

- Perform routine oil testing and checks to avoid damage from contaminants.

- Partner with a gearbox repair team to prevent the consequences of expensive downtime.

- Establish an efficient filtration system using the correct filter to ensure a gearbox doesn’t come into contact with particles and contaminants.

- Review and discover additional ways to protect the well-being of your speed reducer.

HOW TO CHOOSE THE BEST GEARBOX DISTRIBUTOR

Experience matters. We recommend shopping around or seeking out recommendations as primers. Still, at a minimum, your gearbox and industrial parts supplier must have the following qualities to be considered reliable:

- Be an established surplus gearbox distributor and an agent of Rexnord’s Industrial Service division

- Have access to an extensive inventory of new and used Falk parts, including rare components

- Be a trusted partner who delivers exceptional service while being available 24/7

- Understand industrial challenges and have the knowledge and expertise to address those needs

- Provide the best Falk speed reducer repair services nationally

We’re proud to offer all of those advantages and more to our customers. That’s why we committed ourselves to helping companies find the right parts and repair services that keep any job in the right gear.

If you want to learn more or speak with one of our specialists, contact us today. We are available 24/7 to help you with your industrial gearbox needs.