Gearboxes help companies fulfill needed processes by creating maximum power at a minimum cost. The primary purpose of a gearbox is to increase output torque or change speed.

Industrial gearboxes are essential for both manufacturing products and maintaining systems. But how many types of industrial gearboxes are there?

5 Kinds of Industrial Gearboxes

Let’s take a deeper look into five gearbox types: worm, helical, bevel, spur, and planetary.

Worm

A worm gear is a spiral-threaded shaft that drives a toothed wheel. They are essentially screws butted up against what looks like spur gears with angled and curved teeth. Worm gearboxes are usually made of steel, while the wheels are typically brass.

After receiving rotational power from a motor or engine, the worm rotates against the wheel. The screw face pushes the wheel teeth, pushing the wheel against the load.

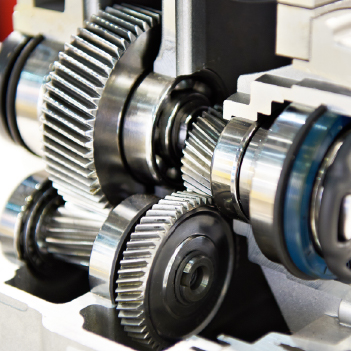

Helical

The teeth in helical gearboxes are locked at 90-degree angles to the shaft. More than one tooth is in contact as they turn so they can carry more load. The load sharing also makes helical gearboxes run more smoothly and quietly than other gearbox types.

Helical gearboxes are particularly suited for heavy-duty operations and are used in most enclosed gear drives. Low power and compact, helical gears are often found in plastics, rubber, cement, and similar heavy industrial settings and applications, including crushers, coolers, extruders, and conveyors.

Bevel

Bevel gearboxes have a curved set of teeth on a cone-shaped surface close to the rim, providing rotary motion between non-parallel shafts intersecting at a 90-degree angle. Quiet and smooth compared to spur gears, they are generally more expensive and do not transmit as much torque per size parallel shaft arrangement.

Bevel gears are often used in automation, quarries, and the mining industry. They are the most common gearbox for power transmissions.

Spur

Spur is both the simplest and the most common type of gearbox. Their straight teeth are parallel to the gear axis, making them accessible and comparatively inexpensive to design and manufacture.

Spur gearboxes are highly efficient and transmit a lot of power through parallel shafts. The teeth parallel to the axis cause the gears to produce radial, instead of axial, reaction loads on the shaft.

Spur gears tend to be noisier than many other gears. Although they run well at slow and moderate speeds, they vibrate at higher speeds.

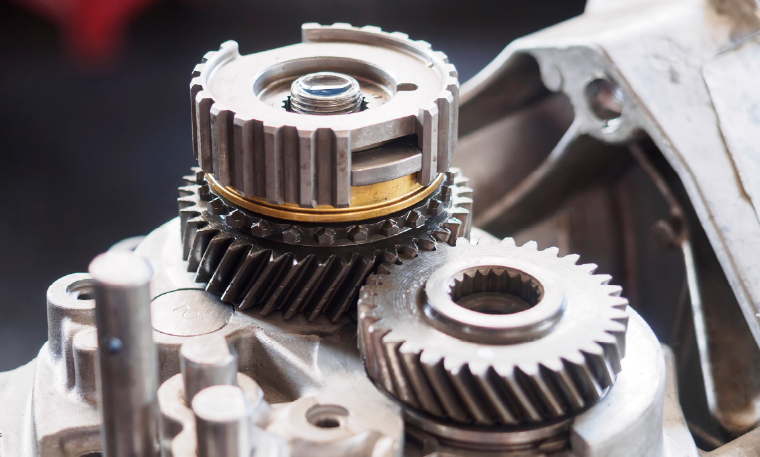

Planetary

The planetary gearbox was functionally described by da Vinci in 1490 and has been used for centuries. The name comes from the fact that its gear formation resembles the solar system. A central gear (sun gear) is surrounded by three or four smaller gears (planet gears). This formation equally moves power through the gears, creating high torque in a small space.

Each gearbox contains a lubricant to ensure the gears function well and wear as little as possible. In addition, the lubricant helps with cooling and vibration.

Contact Our Falk Gearbox Distributors

At NW Industrial Sales, LLC, we carry all the products and parts that industries need to have on hand for their applications, including a vast inventory of Falk reducers, parts, obsolete units, and more.

The cornerstone of NW Industrial Sales, LLC is our industry knowledge. Our specialists have over 75 years of combined experience and can answer your questions, provide solutions, and deliver the finest products. Plus, we’re available 24/7 for all your needs.

Combine the right Falk gearboxes, parts, and surplus gear reducers with intelligent planning and management practices, and you can dramatically reduce unexpected downtime. As agents of Rexnord’s Industrial Services division, we also have access to a nationwide network for repair, remanufacturing, and predictive maintenance services.

Contact NW Industrial Sales, LLC to speak to a member of our team.