Industrial machinery demands adaptability. As a result, some equipment requires gearboxes that offer several pairs of gears aligned to support multi-layered transmissions. As a result, we’ve asked our Falk repair service team to provide insight into multi-stage gearboxes by Falk.

What is a Gear Stage?

Multi-stage gearboxes combine two or more pairs of gears to reach higher transmission ratios than single-stage speed reducers. In this case, each gear stage has a specific ratio, determined by the teeth and the individual gear ratios throughout each step.

Imagine you have a two-stage Falk gearbox. Inside the housing is a series of gears connected to offer more speed control based on the service factor.

The first stage has a gear ratio of 4:1, while the second has a 5:1 ratio. Multiplied together, you end up with a total gear ratio of 20:1. Here, the gearbox produces 20 times more torque than the motor releases. On the opposite side, the output speed is slowed down to 1/20th of the motor’s speed.

In practical terms, separate gears connect and adjust the speed through each step to reach the desired torque based on a specific application. The gears inside the housing are set up on a linear plain that allows each step to better control the speed from the input to the output shafts.

How Many Gear Stages Can a Falk Speed Reducer Have?

The application and the engineering requirements set the stage regarding quantity in most cases. Theoretically, you could have as many as you want, but it wouldn’t make sense to use more than what’s necessary.

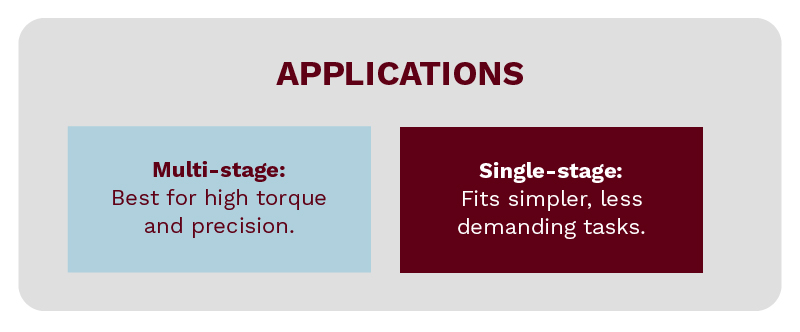

For example, single-stage gearboxes are suitable for more straightforward tasks. At the same time, speed reducers with four or even five stages are ideal for more demanding applications such as mining and agriculture.

Nevertheless, here’s what our Falk gearbox technicians recommend when trying to decide how many stages a gearbox needs:

Your Output Requirements

Every gear stage impacts the transmission ratio. Therefore, doubling the gear ratio of a stage also means doubling the transmission percentage.

The more speed reduction or torque you need, the more stages you may require. For example, mining crushers and offshore marine equipment often use multiple-stage surplus gearboxes to sustain workloads at steady torque levels.

Still, more stages may introduce more friction and energy loss. Regardless, Falk’s engineering aims to balance this trade-off by delivering world-class engineering that promotes improved workflows.

Your Space Constraints

Multi-stage speed reducers can offer higher gear ratios in a more compact design. For example, if you’re using a single-stage gearbox with a larger transmission ratio that’s cumbersome, you could theoretically use a more compact speed reducer by Falk that divides the torque over several stages using smaller gears.

Watch: How does a transmission work?

You Demand Precision

You can achieve more precise torque control by distributing the load across multiple gear stages. This is particularly beneficial in applications where precision matters, such as robotics, where subtle changes in torque can significantly impact performance or product quality.

Your Application

Some industries or processes may have particular requirements that influence the number of stages needed. Plus, we know how important it is to match the Falk gearbox to your application, particularly if you need a multi-stage speed reducer.

At NW Industrial Sales LLC., we’ve been the go-to resource for speed reducer repair services and surplus gearing by helping businesses in the following spaces:

- The agriculture and grain industry

- The mining industry

- Oil and gas companies

- Power and energy businesses

- The offshore and marine industry

- The chemical and refinery space

- And various other industries seeking gearbox support

The 5 Advantages of a Multi-Stage Falk Gearbox

1) Reduced backlash: Less backlash means more precise positioning and smoother operation, especially in reversing applications.

2) Smoother power transmission: Multiple stages mean a gearbox will distribute the load across more teeth, reducing wear while elevating precision.

3) Customization: Multiple stages allow more design flexibility, particularly when it comes to planetary gearboxes.

4) Vibration reduction: Multi-stage gearboxes by Falk may dampen vibrations while improving efficiency.

5) More compact design: Switching from a larger single-stage speed reducer with a larger gear ratio to a smaller multi-stage unit alleviates space.

NW Industrial Sales, LLC: Your Surplus Multi-Gearbox Provider

NW Industrial Sales LLC is your trusted partner for multi-stage gearbox solutions. With expertise across several diverse industries, we offer surplus gearing and speed reducer repair services tailored to your specific needs.

Contact us today to optimize your industrial machinery with Falk multi-stage gearboxes alongside our expert support.