Falk has manufactured their gearboxes at their campus in Milwaukee, Wisconsin, since 1910. Their continual innovation has allowed them to push the envelope of industrial technology for over a century, creating a legacy established on quality and dependability that continues today.

Innovation, coupled with the rise in new machinery across growing industries, means the development of gearbox technology is far from over. That’s why we decided to examine emerging trends to provide context around gear reducer evolution and explain how gearboxes will continue to drive businesses forward.

Geared in Humble Beginnings

In part, gearboxes became a primary solution for industrial businesses to produce torque more cost-effectively than direct drive motors. That spurred an extensive growth period that found Falk developing everything from worm, helical, spur, and other gearing under different configurations needed for hundreds of new applications.

Falk’s engineering team continued to innovate by making more compact, efficient, and resilient speed reducers using the best materials to ensure longevity. In turn, industries such as mining, agriculture, manufacturing, and others depend on their gearing because they offer:

- A high load-handling capacity

- Energy efficiency

- An ability to withstand extreme temperatures and environmental conditions

- Extraordinary mechanical strength to power through rugged conditions

The Future of Gearboxes Explained

The advantages listed above increased the adoption rate of gearboxes for industrial purposes and mechanical engineering that continues today. However, we’re seeing a growing demand to make gearboxes more sustainable and efficient with the help of technology and newly designed applications.

Let’s look at a few examples to illustrate how gearbox technologies will evolve in the coming years.

Energy-Efficient Designs Will Become Standard Practice

The increasing need for renewable energy means the power industry is embracing new ways to produce electricity more efficiently without fossil fuels. Hydro and wind power are primary examples.

Turbines producing power under those conditions require a gearbox to generate electricity from a low-speed rotor at higher rotational speeds. While that technology has advanced over the last decade, renewable energy sources like wind will evolve over the coming years as new utilities surface. As that happens, gearbox technologies will develop alongside them.

More Vehicles Will Leverage Torque With Sustainability in Mind

Engineers are constantly looking for ways to increase efficiency by leveraging torque. For example, the latest Volkswagen Passat includes a newly designed gearbox with a fuel-saving “down-speeding” feature that allows the car to run at higher gears at lower torque.

Still, Volkswagen isn’t the only automotive manufacturer using torque controlled by gearboxes to improve efficiency for sustainable purposes. Ford and GM are also future-proofing their cars using 10-speed gearboxes to optimize their vehicles.

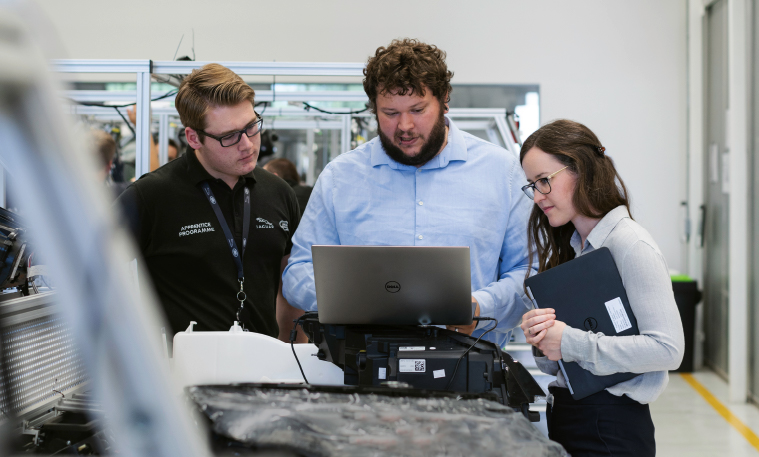

Mechanical Designs Will Embrace Technology

We’re intrigued by the continued adaptation of modern technology and traditional mechanical engineering in speed reducer designs. That’s why “smart gearboxes” are gradually being applied to specific applications that leverage internal sensors, machine learning, and other means to work more efficiently.

What’s more, new gearbox technologies like these also produce performance data that could streamline workflows and diagnose equipment performance.

New Applications Mean More Opportunities

Renewable energy devices, electric vehicles, and manufacturing equipment might be the primary verticals taking advantage of gearbox advancements. However, new opportunities will undoubtedly surface as companies move towards more sustainable means and companies like Falk look to the future.

Connect With Our Falk Surplus Gearing & Parts Distributors

We offer a vast inventory of new and used surplus Falk gearing, including hard-to-find parts rarely found elsewhere. Additionally, our technicians are here to provide professional on-site repair and renewal services 24/7.

Simply give us a call at 503-468-0454 or fill out the contact form and one of our team members will follow up ASAP.