One of the best ways you can increase the longevity of a gearbox is by maintaining its filtration system. An inadequate system can result in costly repairs, downtime, and the need to replace the gearbox.

Maintenance programs that service gearbox lubrication systems can save valuable time and money allowing the industrial gearbox to continue to perform at peak efficiency throughout its life cycle.

The Importance of Gear Reducer Filtration

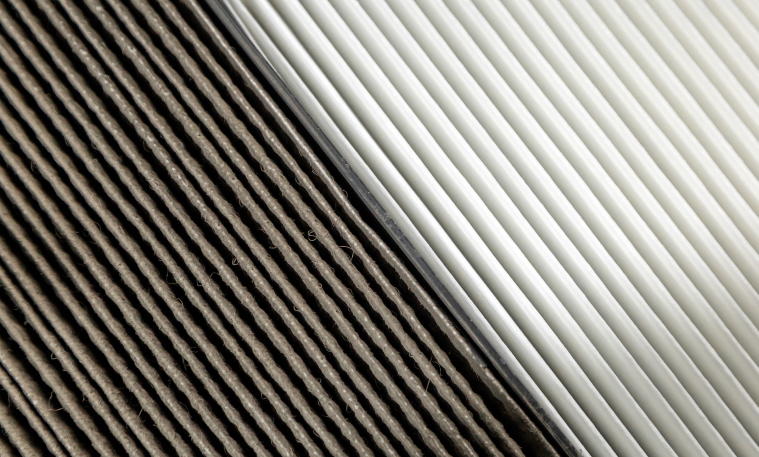

An industrial gearbox is a complex piece of machinery that requires regular maintenance to function at peak efficiency. Oil cleanliness is key to minimizing costs for repairs, rebuilds, or downtime.

Industrial gearbox oil tends to have a high viscosity, which means it is more difficult to filter. Simply draining and refilling it is not enough to provide the best level of cleanliness. Often small particles and residues are left behind, requiring filtration.

By choosing the right oil viscosity and the correct filter housing and filter, industries can reduce downtime. The temperature of the oil affects the viscosity, requiring some management to ensure that a maintenance team is able to reach their cleanliness targets efficiently. The long-term benefit of a routine maintenance program is a very cost-effective way to drive savings.

Identifying Gearbox Contamination

A gearbox can become contaminated when a foreign body or matter infiltrates the system and damages the unit or negatively affects its effectiveness or operation.

Some common contaminants include:

Hard particles

- Moisture

- Aeration

- Radiation

- Chemical matter

Contaminants can enter the gearbox from a number of entry points, including the seals and breathers. Other sources of contamination can be the result of maintenance activities like top-ups, drains and refills of oil, and other types of servicing.

Another factor to consider is the ambient condition in which the gear reducer operates. This could be a major source of contamination. For example, wet conditions increase the chance that moisture will find its way into the gearbox. A hot and dry environment can cause more particulate matter to infiltrate the gearbox.

Minimizing Sources of Contamination

After identifying sources of contamination, consider how it can be minimized. You may be able to engineer changes to prevent contamination. Otherwise, it is best to call on an expert to identify and create a plan to reduce contamination of the filtration system.

Here are some points to consider when developing this plan:

- Seals: Be sure to check and replace seals to keep oil leakage and contamination to a minimum. At NW Industrial Sales, LLC we offer a wide range of fluid sealing solutions.

- Breathers: By upgrading a vent to a proper contaminant exclusion breather, you can minimize the ingress of small particles and moisture. For a moist environment, use a desiccating breather

- Portable Offline Filtration: In some cases, a gear reducer may not be equipped with its own filtration system. Making the appropriate modifications could be too costly and require lengthy downtime. Using a portable offline filtration system can help keep the oil free of contaminants.

- Permanent Offline Filtration: In applications that require the filtration of large amounts of oil or when high levels of cleanliness are needed to be maintained, a permanent offline filtration circuit can be employed.

By keeping a regular maintenance schedule, upgrading seals and breathers when needed, and incorporating portable or permanent filtration systems, the longevity of a gear reducer can be maintained.

Your Source for Falk Gearboxes, Surplus Parts & More

NW Industrial Sales, LLC can help you find the best type of gearbox for your application. We have a combined 70 years of experience serving multiple industries. We also have a large inventory of Falk gearboxes and gearbox parts. Plus, agents of Rexnord Industrial Services, our clients have access to their nationwide maintenance network.

If you would like to learn more or speak with one of our specialists, contact us today. We are available 24/7 to help you.

Hard particles

Hard particles