Falk gear couplings form important parts of many industrial machines. Couplings are used to connect two shafts together at their ends in order to transmit power. They can be most broadly defined as mechanical devices that serve to connect the ends of adjacent parts. Selecting the right coupling for your application can save maintenance costs and reduce downtime.

Falk Lifelign Couplings for Industrial Applications

Falk gear couplings can be used for a wide variety of industrial applications and across many industries, including food, aerospace, and medical.

Couplings are used to move power from one end to another, such as transferring power from a motor to a pump.

Other common reasons they’re utilized are to:

- Change the vibration characteristics of rotating units

- Slip when an overload occurs

- Introduce protection

- Connect driving and driven parts

- Lessen the transmission of shock loads from one shaft to another

A typical coupling has two flexible joints, with one fixed to each shaft. These joints often have a third shaft that connects them, called the spindle. Each joint most often has a 1:1 ratio of internal and external gear pairs. They come in two basic variations, flanged sleeve and continuous sleeve.

From high-heat and high-humidity applications to corrosive environments to high-torque applications, we can provide the perfect coupling solution to ensure your project completes without a hitch.

How Do You Select a Falk Lifelign Gear Coupling?

Before you can choose the right Falk Lifelign Gear Coupling, you need to be sure you have the following information on hand.

You will need to know:

- How much horsepower or torque will be applied

- The running RPM

- The application or what equipment will be connected, like a motor to a pump

- Shaft diameters

- Shaft gaps

- Any limitations in the physical space

- Special bore or finish information and the type of fit needed

There are some exceptions, however. If you have high peak loads, brake applications, or an axial slide frequency of more than five per hour. You will have to use a formula selection method. If your application requires rapid changes in direction or torque reversals, please refer to the factory.

6 Steps to Take When Choosing Your Falk Lifelign Gear Coupling

In order to choose a coupling in the standard manner, follow these steps:

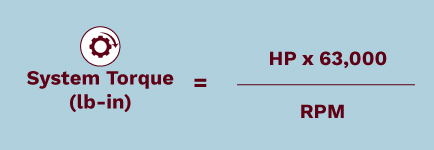

1) Find the rating of the system torque. If this is not given you can find it with the formula of horsepower multiplied by 63,000 divided by RPM. Horsepower here is the actual or transmitted power required by the application, and RPM is the actual speed the coupling is rotating.If torque is not given, calculate as shown below:

2) Determine the appropriate service factor via the manufacturer’s guidelines.

3) Determine the minimum coupling rating by multiplying the service factor by the torque.

4) Once you have this information, you can determine the appropriate coupling type.

5) Then determine the proper size by choosing the coupling size that has a torque rating that is equal or greater than the rating determined in step 3.

6) Next, check the coupling’s capacities and dimensions. These include:

- Bores

- Speeds

- Dimensions

As Rexnord distributors for Falk Lifelign Gear Couplings, we provide products that are high in quality, reliability, and easy to maintain. We are able to accommodate many different shaft fits and hub styles, allowing us to provide a solution for the needs of your unique application.

Falk Lifelign Gear Couplings at NW Industrial Sales, LLC

NW Industrial, LLC offers over 75 years of experience and a vast inventory of Falk coupling parts. As Rexnord distributors, we are able to leverage a nationwide network of repair shops and other services. Let us take care of you from start to finish. Contact us today.