Whether you use industrial equipment in the manufacturing, agriculture, or mining industries, gear drives are essential for guaranteeing the productivity and profitability of your operation. Learn more about both the advantages and potential challenges of gearbox operation.

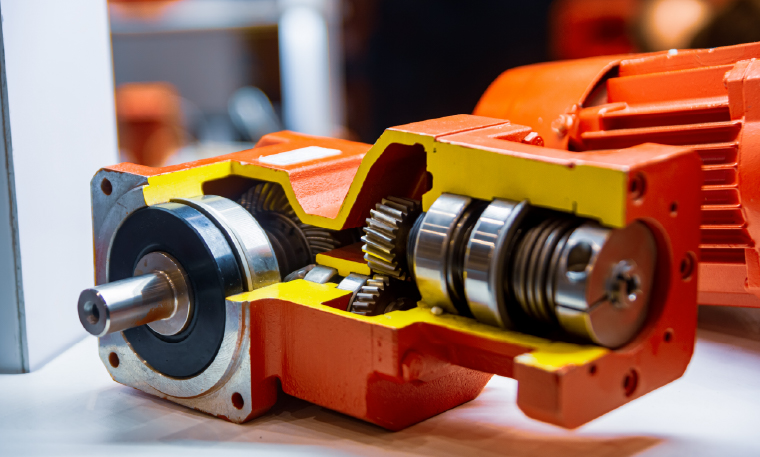

What is the Function of a Gearbox?

No matter what machinery they are used in, the primary purpose of a gearbox is to increase the output torque of a motor or change its speed. As such, gear drives help optimize a motor’s performance, while also providing increased durability and precision.

3 Advantages of Industrial Gearboxes

Industrial gearboxes are used in a variety of industries and offer huge benefits when it comes to the performance of industrial applications.

Improve Operational Efficiency

Because gear drives are built specifically to increase the output torque of a motor, they improve operational efficiency. In turn, gear drives allow your machines to run more economically because they do more with less. To illustrate, when you use several gear drives in a large production line, you maximize manufacturing output while minimizing resource usage.

Support Heavy-Duty Applications

Gearboxes are engineered specifically for the rigors of industrial settings. You can trust Falk gear drives will help keep your motors operational when you need them most—whether to meet a shipping deadline or keep your agricultural machines running at peak performance.

Provide Precision Machining

Gear reducers, such as planetary gearboxes, provide accuracy and precision in industries such as robotics and 3D printing. In planetary gearbox design, a central gear is encircled by a number of smaller gears. This arrangement resembles a solar system. Due to their efficient design, they create high torque in relatively small spaces.

3 Disadvantages of Industrial Gearboxes

Gear drives are critical components in machinery and equipment, yet most problems arise due to improper care and maintenance.

Wear & Tear Over Time

If gear drives aren’t properly serviced and lubricated, they will start to break down. Not only can damaged gear drives grind the production at your facility to a halt, but they can also put employees in danger. In fact, broken gearboxes often create loud noises that can cause hearing damage if left unchecked.

Backlash

Backlash results from the amount of spacing between the teeth of a gear train. When you switch a gear train into reverse, the amount of time it takes to reengage is indicative of backlash. While a little backlash is okay, excessive space between teeth can cause major problems. On a large assembly line when many parts are interconnected, reverberations that begin from one set of gear teeth can spread across the whole system and cause major damage.

Outdated & Discontinued Components

When outdated parts are broken or damaged, it can be a challenge to replace them. In some cases, gear drives are old enough that they are no longer supported by their original manufacturers. It’s of utmost importance to find a gearbox motor supplier and repair vendor with the expertise to fix and supply OEM components, while also being able to update them with modern parts if necessary.

Our Gearbox Motor Suppliers Provide Expert Repair & Renew Services

Almost all the disadvantages that come about with gear drives are the result of heavy industrial use coupled with improper care. You can circumvent a vast majority of these issues by working with a qualified Falk parts repair and supply service.

As agents of Rexnord’s Industrial Services division, NW Industrial Sales, LLC has access to a nationwide network of talented technicians and a vast inventory of surplus parts.

Contact us to learn more about our onsite Falk gear drive system repair, restoration, worn part replacement, damaged assembly repair, and more.