A common question asked about conveyors is, “How do I choose a conveyor gearbox?” The answer can be complex and a little daunting at first. In today’s article we will break down what exactly causes conveyor shock load failures, how to choose from a selection of gearboxes for belt conveyors, and why having a surplus of Falk gearbox parts on hand is key to maintaining profitability.

Why Conveyor Belts Fail

For processes where the product remains a consistent weight and size failures are less common. However, variances often happen during the production process as components are added. This can lead to extreme shock loads as the products drop onto a conveyor.

The extra load causes the gear reducer in the conveyor belt to try to compensate for the additional weight by increasing the torque, and consequently increasing the draw from the motor. A series of excessive shock loads increase the gear reducer’s chance of failing.

A shock load can also occur when the gear reducer is forced to make starts or stops suddenly. This sudden start or stop puts a lot of stress on the gear teeth, which causes failures due to metal fatigue.

How to Protect Belt Conveyors from Shock Loads

When developing a new application it is important to ask how the product will be loaded and unloaded at each phase of production. In applications where conveyor belts will be dropping or moving product from one belt to another, or where product is dropped onto a conveyor belt, it is important to anticipate shock loading.

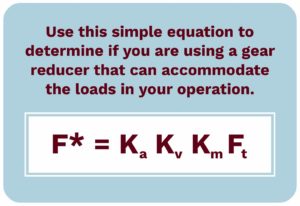

- Ka is the application factor. This allows for the non-uniformity of input or output torque that is inherent to the machinery connected to the gears, in this case the conveyor belt.

- Kv is the dynamic factor. It accounts for the tooth loads generated by gear mesh stiffness and gear imbalance.

- Km is the load distribution factor, which represents the non-uniformity of tooth loading over the width of the teeth.

- Ft is the service design load.

You will want to choose the gear reducer that fits the service factor of your application. Applications are divided into service factors based on the hours of operation and shock loads. You can think of the service factor as a safety factor. This safety factor ensures the gearbox is able to meet the requirements of the application.

Quick Tips to Reduce Shock Load

The following tips can help to reduce the impact of a shock load on your operation.

- Don’t exceed the conveyor belt’s capacities. These capacities include the structural capacity and drive capacity.

- Lubricate the springs on a spring balanced gate.

- Lubricate conveyor belt gear reducers with the manufacturer recommended product.

- Ensure employee safety by training on all safety warnings on the conveyor belt.

- Keep a healthy stock of spare parts.

- Bolt permanent conveyors to the floors.

- Increase the horsepower as the conveyor speed increases.

How to Choose a Falk Industrial Gearbox for Your Conveyor

There are a number of factors to consider when choosing the right conveyor belt gearbox for your application. Our experts can quickly determine the needs of your application and recommend durable and reliable products, like Falk gearboxes.

Conveyor gearboxes need to be able to withstand a variety of operating conditions, from variable loads, to environmental impacts like temperature and dust. With over 70 years of experience, and a large inventory of Falk gearboxes, gearbox parts, and gear reducers, NW Industrial Sales, LLC can help ensure that your conveyor belts are able to endure any shock loads. When you work with NW Industrial Sales, LLC you also get access to Rexnord Industrial Services and nationwide maintenance network.

If you would like to learn more, or speak with one of our specialists, contact us today. We are available 24/7 to help you.