Reverse engineering a gearbox involves meticulous examination while considering every variable that may have caused an issue. It can be complicated, but that’s why our Falk repair team finds it to be such a fascinating challenge—especially if they can’t access the original design documents or plans.

Given the enthusiasm concerning this topic, we assigned our technicians to define reverse engineering and how it applies to gearboxes.

Gearbox Reverse Engineering Defined

Many refer to reverse engineering as both an art and a science because it balances mathematics with mechanical artistry.

At its core, reverse engineering a gearbox means taking the speed reducer apart piece by piece to learn how and why each component works together. Our gearbox technicians then examine every detail to understand what broke, how it worked, and how we’ll renew it.

Still, even that simplified description doesn’t communicate the technical demands and skill required to re-engineer a gearbox back to its original form if the proper documentation or OEM parts are unavailable.

Fortunately, as gearbox motor suppliers, we have access to a wealth of resources and hard-to-find parts to make the stages of reverse engineering a gearbox easier.

Need to repair or renew your Falk gearbox? Learn more about our services.

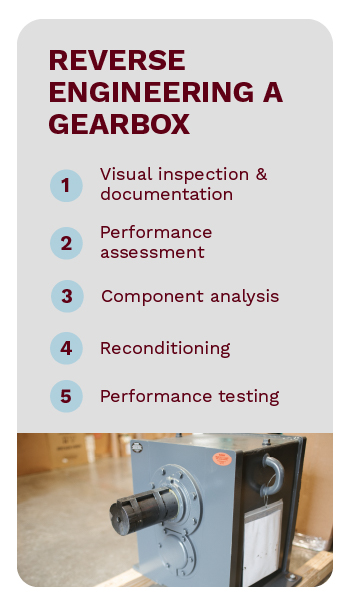

The Stages of Reverse Engineering an Industrial Gearbox

Our Falk industrial repair team often reverse engineers an industrial gearbox in stages. Those stages allow us to take a holistic approach to enable us to understand:

- Why the gearbox failed

- How it worked

- And carefully consider how we can return it to a customer in like-new condition

The stages of reengineering a gearbox often find us performing the following tasks:

Visual Inspection & Documentation

Visual Inspection & Documentation

We start by visually inspecting the speed reducer and taking notes concerning:

- The general condition

- Any visible wear and tear such as brinelling, spalling, and misalignment

- Signs of overheating

- Its parts and branding

- How it was used and the conditions it will be used in

- And any other noteworthy details such as contamination

Think of this stage as a before shot that tells us whether the gearbox needs a complete rebuild instead of simply replacing parts like the bearings.

Initial Performance Assessment

We always thoroughly test a speed reducer before taking a Falk gearbox apart to give us a baseline of performance data such as:

- Efficiency and torque performance

- Noise levels

- Heat generation

- And any other signs of wear and tear or contamination

Disassembly & Component Analysis

The next stage involves our repair team taking every gear, bearing, and shaft apart, measuring it, and inspecting the unit further. We also drain all oils and lubricants, which we replace later.

Here, we examine the gearing teeth, pitch diameters, and any other signs of wear that provide context on what went wrong. It’s meticulous work, but also is the foundation of the whole process.

Remanufacturing & Reconditioning

We then rebuild or replace the shafts, casings, bearings, and various elements to ensure the gearbox returns to its original shape or better.

In some instances, we may use advanced restoration methods, including precision finishing, surface smoothing, or metal deposition, to refurbish parts to align with the original manufacturer’s standards.

Replacing Fluids & Seals

Next, we replace all lubricants and fluids to match any applicable needs. Our team also installs new seals throughout the system to prevent potential leakage and minimize the risk of contamination or future complications.

Reassembly

Now that we’ve remanufactured, restored the fluids, and replaced damaged parts, we simply reassemble the unit and prepare it for a series of thorough tests.

Final Performance Testing

With the gearbox reassembled, we run several tests to make sure the rebuilt gearbox meets or exceeds the original performance specifications. This includes:

- Rotational dynamics assessments

- Casing pressure checks

- Vibration tests

- Lubricant circulation trials with contaminant filtration

Only if the unit passes our tests will we be assured that we’ve successfully reengineered a speed reducer to meet our high standards.

NW Industrial Sales, LLC: The Best Falk Repair & Renewal Team

Ready to experience top-tier Falk gearbox repair and renewal services? Our skilled technicians are standing by to breathe new life into your industrial gearboxes by offering nationwide support, including an extensive inventory of new and used parts.

Contact our Falk repair team today for professional reverse engineering and restoration services to ensure your industrial operation stays in the right gear.

Visual Inspection & Documentation

Visual Inspection & Documentation