Falk RAM mixer gear drives are specifically designed and built with the demanding requirements of a variety of mixing applications. Industries, as varied as waste and water management and cement, rely on Falk RAM mixer gear drives for their industrial mixer applications. They are able to handle the application requirements of industries such as food processing, chemical processing, mining, and pulp and paper.

Why Do Industries Rely on Falk RAM Mixer Gear Drives?

Here we share five reasons why industries rely on Falk gears for their industrial mixing equipment.

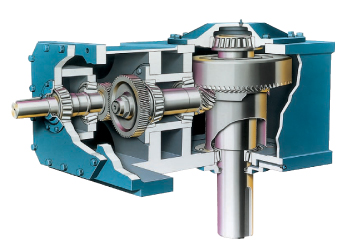

1) Industrial Mixing Equipment Adaptable to Any Application

![]()

An industrial mixer is defined as “a circuit that takes two input signals and mixes them in a special way to produce new output signals.” This means they can be used in practically any industry where two input signals need to be combined. Mixer gears are used to transmit power from “one rotating shaft to another.”

It is also designed to endure the typical mixing requirements:

- High bending and thrust loads on the output shaft

- No leakage of gear lubricant into the product

- Reliable 24 hour operation

Falk mixer drives are very flexible and are available with solid or hollow output shafts. They can be adapted to allow for top, bottom, or side entry mixing.

2) Designed Specifically for Mixing

There are three sizes of Falk RAM mixer gear drives that can be further adapted to your application. Each is designed specifically to ensure lasting and precise mixing. Features include:

- A cast-iron housing to accept the stresses of mixing while maintaining accurate gear alignment and resisting corrosion

- A C-Face motor adaptor to create fast, positive motor alignment.

- A configurable mounting to allow for a wide range of applications.

- High strength helical gearing for high efficiency and maximum load capacity.

3) No Contamination of Product

One of the most important requirements of an industrial mixer is to ensure there is no contamination of the product with the lubricant used in the gear drive. Falk RAM mixers meet that requirement for industrial mixing equipment with their no-leak drywell construction.

The mixer gear drive’s construction isolates the oil sump from the output shaft. This prevents gear lubricants from leaking and contaminating the product. On medium-capacity mixers, this includes a drywell to isolate the low-speed output shaft to prevent lubricant contamination.

4) Extreme Flexibility

With three capacity sizes, multiple mounting configurations, multiple shaft options, and mixing entry points, there is practically no mixing application that can’t be completed with a Falk RAM mixer gear drive. Industrial mixing equipment requires that it be fitted to its application. Falk mixer drives allow you to adapt to the changing needs of any project.

With three capacity sizes, multiple mounting configurations, multiple shaft options, and mixing entry points, there is practically no mixing application that can’t be completed with a Falk RAM mixer gear drive. Industrial mixing equipment requires that it be fitted to its application. Falk mixer drives allow you to adapt to the changing needs of any project.

Each size mixer is capable of loading in at least two entry points, and the medium and large capacity Falk mixer drives offer both hollow and solid output shafts. They are also rated for a varying degree of output torque and mixing ratios.

5) Backed by Rexnord

Whether it is an optional stub shaft or easy installation, FALK RAM mixer gear drives offer the best solution. We are proud to offer an extensive inventory of Falk mixer gear drives, Falk surplus parts and gearboxes, and more.

As certified agents for Rexnord’s Industrial Services division, we are distributors of OEM gearing and parts provide expert repair and maintenance services. Rexnord’s field service technicians are known for their repair expertise and predictive maintenance. We are available 24 hours, 7 days a week to connect you with an industry expert who can customize a solution to your needs.