If you are looking for a way to lower drive cost, you will want to focus on industrial gear reducer efficiency. Industrial gearboxes and gear reducers are used in myriad applications across multiple industries. However, not every industrial gear reducer is right for every job. Pairing the right gear reducer to the right job can translate to significant savings over time.

In today’s article, we’ll take a look at what you can do to increase the efficiency of your industrial gearboxes by choosing the right gear reducers, the right gearbox lubrication, and knowing when to seek out industrial gearbox repair.

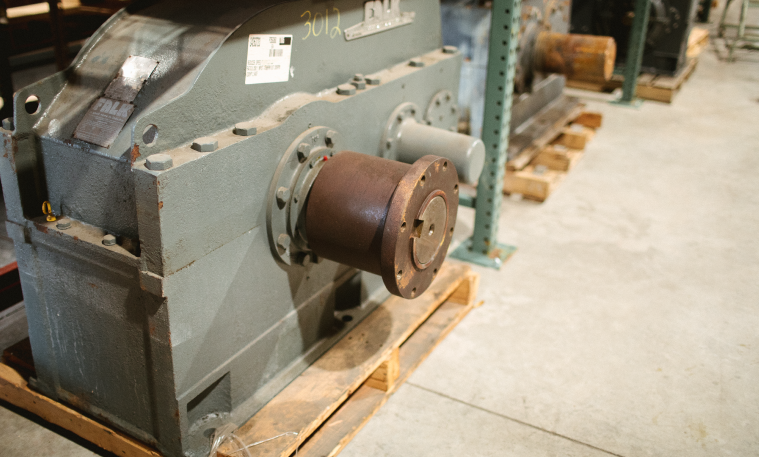

Choose the Right Type of Industrial Falk Gearbox

The Worm Gear Reducer

The worm gear reducer is one of the more widely used speed reducers. The worm gear reducer is made up of two elements, the worm screw and worm gear, or wheel. There can be some confusion as the term worm gear is often used to describe the entire worm drive as a unit.

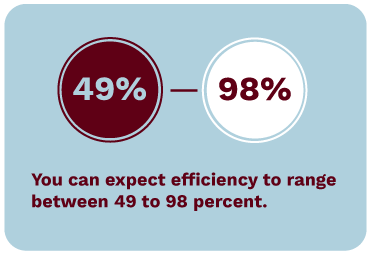

Each full rotation of the worm screw advances the wheel by one tooth. Heat is generated due to friction while the screw slides against the wheel, limiting the efficiency of worm drives to 30 to 90 percent. This can be managed somewhat by using dissimilar metals for the worm and the wheel to minimize friction.

The Helical Worm Gear Reducer

How the gears are arranged in an industrial gearbox affects the efficiency of the unit. Helical worm gear reducers use a set of helical gears that are connected to a motor shaft which drives the worm-gear set. The helical gears keep the reduction ratio low to maximize efficiency by reducing the input speed from the motor shaft.

Because the leading edges of the teeth are set at an angle to the axis of rotation, helical gears can operate more smoothly and quietly than spur gear teeth. Their efficiency ratio ranges from 79 to 90 percent depending on the ratio.

The Helical Bevel Gear Reducer

With a helical bevel gear reducer, the output shaft is at a right angle to the motor shaft. And like helical worm gear reducers, the first speed reduction is made by a set of helical gears. When spiral-bevel gears are mounted with intersecting axes friction is minimized, allowing the gear reducer to provide 94 to 97 percent efficiency.

However, there is a potential drawback. Helical bevel gear reducers are often priced higher than worm-gears, especially if the application calls for smaller ratios. However, the cost can sometimes be offset because of the high efficiency that the gears provide, or the benefit of having a smaller motor and/or gearbox for your application.

How to Calculate Industrial Gearbox Efficiency

To calculate the load requirement you want to determine how much actual torque or power is needed to drive the load. After you have that figure, then multiply the torque or power by whatever service factors might apply.

Be sure to factor in the usual and unusual operating conditions that the application might experience. These can include frequent stopping and starting, temperature changes or extreme temperatures, cleanliness factors, or shock loads. These are often listed in the manufacturer’s catalog. You can also check with the American Gear Manufacturers Association which provides up-to-date information on service factors.

After applying the recommended service factors, you can compare the efficiency of the gear reducers you are considering based on the actual load requirements.

Save Money & Increase Efficiency With Industrial Falk Gear Reducers

You can see the impact of gear efficiency in both the costs of the drive components and the operating costs. Even if two gear reducers provided the same ratio, you might consider how using a higher efficiency gear reducer would allow for a smaller, and thus more inexpensive, motor.

Another added benefit of an efficient industrial gear reducer is the savings on energy costs. A higher efficiency gear reducer requires a smaller motor which in turn uses less energy. This can result in hundreds of dollars in savings depending on the application.

If you are considering how you might best improve the efficiency of your industrial gear reducers or Falk gearboxes, NW Industrial Sales, LLC offers over 70 years of combined experience serving industries as diverse as marine and pulp and paper.

We offer Falk products and fluid sealing solutions, in addition to our expansive inventory of spare gearbox parts, gear reducers, and more. We are also proud agents of Rexnord Industrial Services, which grants you access to their nationwide maintenance network.

If you would like to learn more, or speak with one of our specialists, contact us today. We are available 24/7 to help you.