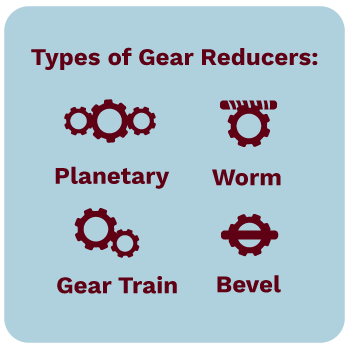

If you are in the market for Falk surplus gear reducers and parts, you may be wondering what the different types of gear reducers are and what applications work best for each type. In this article we will explore the four major types of gear reducers and their applications.

Gear Reducers: The Basics

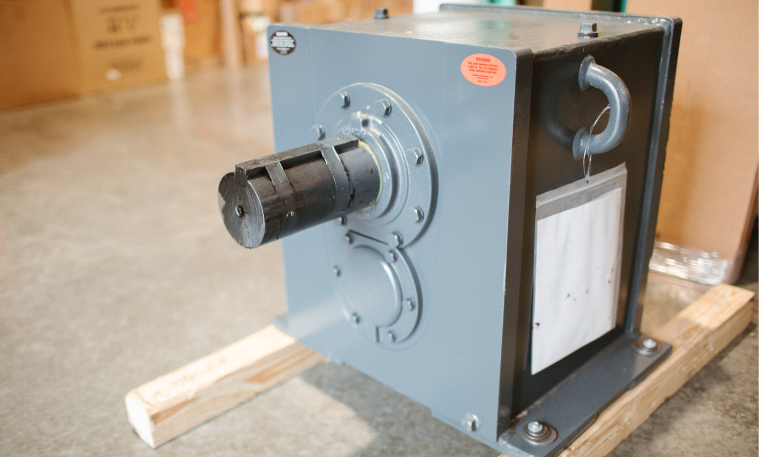

First, let’s take a look at what a gear reducer is. It is used to connect a motor to a driveshaft, and is all or part of a transmission. It allows the operator to modify the torque and speed between the motor and the load.

A gear reducer is sometimes called a gearbox. This is an appropriate name as they consist of a series of gears, each with a gear reduction ratio equal to the number of teeth between the input and output shafts. A gear reducer is what allows for a machine to increase in speed and reverse or output more torque to pull heavy loads.

Before selecting a Falk surplus gear reducer, it is important to know the amount of torque the application will require. A gear reducer will increase the amount of torque the motor can generate. The minimum and maximum torque supported by a product is often indicated by the manufacturer. Also keep in mind what reduction ratio you would use based on the rotational speed of your motor. This is often indicated by the manufacturer and given in revolutions per minute.

Planetary Gear Reducers

Other benefits of a planetary gear reducer include:

- High efficiency

- Low clearance

- High torque to weight ratio

The applications recommended for this kind of reducer are ones that:

- Require high accelerations

- Require slow speed and high torque

Or applications in:

- Machining centers

- Mobile machinery for agricultural work

Worm Gear Reducers

A worm gear reducer is sometimes called a worm drive. The worm is a gear in the shape of a screw that meshes with a worm wheel, which looks something like a spur. It can reduce rotational speed and transmit higher torque like other gear reducers.

These gear reducers are great for applications that require high transmission ratios. The mechanism is also non-reversible, as the worm wheel cannot drive the worm. This allows for greater security in the gear reducer with a lack of slippage.

This type of gear reducer is great for:

- Conveyors

- Winches

- Handling

- Use in combination with other gear reducer types

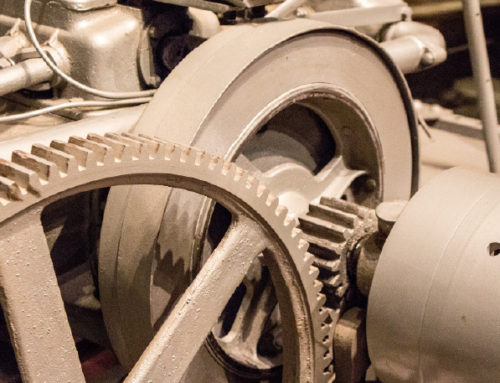

Gear Train Gear Reducers

A gear train simply refers to a system formed by mounting gears on a frame so that the gears engage. This is perhaps the most classic of all gear reducers.

Gear train reducers are used when an application has parallel axes and requires a lot of power. These gear reducers are simple to maintain and to repair, potentially saving money and preventing slowdowns. They have a low reduction ration per gear train, and offer a high level of performance.

The gear train gear reducer can be found in a number of familiar applications:

- Automotive

- Conveyors

- Marine applications

Bevel Gear Reducers

A bevel gear reducer allows you to change the machine’s rotation system. You can switch between a transverse rotation to a longitudinal rotation with the use of a bevel gear reducer. In a bevel gear reducer the axes of two shafts intersect and the gear is conically shaped, allowing them to rotate at an angle.

They are compact and can handle a lot of power. They are great for high torque applications and are quiet and energy efficient. They can be expensive and difficult to maintain, but are widely used in agricultural and public works.

These gear reducers can be found in:

- Power plants

- Differential drives

- Hand drills

- Bevel gear planer

- Rotorcraft drive systems

- Grain mills

NW Industrial Sales, LLC Offers Gear Reducers for Any Application

With 70 plus combined years of experience, NW Industrial Sales, LLC offers Falk surplus gear reducers and parts essential to practically any application. We also have partnered with Rexnord to grant you access to their nationwide network for repair, maintenance and remanufacturing.

Check out our extensive inventory of Falk surplus gear reducers and parts and fluid sealing products or contact us 24/7 for us to help you find the right solution to your application.