Download the Guide

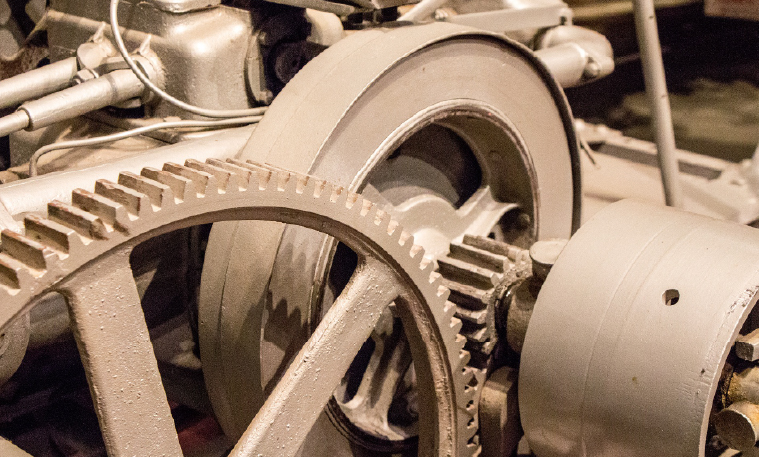

A gearbox has many components, all of which play an important role to ensure proper functioning. Before we examine these components, let’s start by defining what a gearbox is.

A gearbox is a system that is completely enclosed and funnels mechanical energy to an output device. It is made up of a set of gears and their casing, most commonly found in cars, but is widely used in turbines and other heavy machinery.

The reason gearboxes are so important in the running of machinery is that they are able to modify their speed, torque and other attributes to convert energy that can be used in a variety of devices and for a wide range of applications.

The gearbox funnels energy from one rotating power to another to increase the output torque or change the motor’s speed.

5 Gearbox Components to Know

To completely understand what a gearbox is and what it does, it helps to understand the different components and parts.

1) Clutch shaft

The input shaft―also called the clutch shaft―extends from the front of the transmission and carries power from the clutch disc into the transmission. A clutch shaft transfers power from the engine to supply to other shafts.

2) Countershaft

A countershaft is a set of helical gears cast out of a single piece of hardened steel. It transfers power flow from the input shaft drive gear to the output shaft and connects with the clutch shaft directly and is also connected to the main shaft.

It may run at engine speed or at lower than engine speed according to gear ratio. The gears and the countershaft rotate as one and are a one-piece assembly.

3) Main shaft

The main shaft has two gears that slide on splines connected to the shaft. One is known as the first-and-reverse gear, the other as the second-and-third gear. There are only two gears, but each serves a dual purpose. The main shaft has the same direction of rotation as the input shaft.

It runs at the same speed as the vehicle and carries power from the countershaft by use of gears and according to the gear ratio, it runs at different speeds and torque compared to the countershaft. One end of this shaft is connected to the universal shaft.

4) Gears

Gears transmit power from one shaft to another. The amount of torque transmitted by the gears depends on the number of teeth and the size of the gear.

The higher the gear ratio, the higher the torque/acceleration. All the gears are fixed on their respective shafts except the ones on the main shaft; which can slide either direction along the shaft.

Whenever a rotary motion occurs, bearings are required to support the revolving part and reduce the friction. In the gearbox, both the counter and main shafts are supported by bearings.

Within a gearbox, low-speed shafts normally use fixed profile journal bearings, often with simple cylindrical bores. High-speed shafts have used multi-lobe fixed profile bearings in the past, but are increasingly using tilting pad journal bearings.

Can Gearboxes Be Repaired if a Component Breaks?

The short answer? Yes! Gearbox components can require repair from time to time due to normal wear and tear and it’s important to keep on top of it. Anything from damage or wear to the teeth of gears to seal leakage can cause catastrophic failure causing costly delays.

A good maintenance plan should be created and followed to minimize time lost over broken machinery. This plan should include a schedule for inspecting and servicing, replacing parts and keeping track of any parts that need to be ordered.

Contact Us for Your Falk Industrial Gearbox Parts & Services

Falk is known as the industry-leading choice for gear reducers. They set the standard for excellence for both quality and performance. Falk products are adaptable to many applications, provide optimal torque, and can stand up to harsh environments.

At NW Industrial Sales, LLC, you’ll find the highest quality Falk products and parts for your industrial needs. We serve a variety of industries, including agriculture, grain, cement, energy, pulp and paper, and mining. Our knowledgeable team is on hand 24/7 to ensure you receive expert customer service.