When it comes to any industrial job, efficiency is critical for timely completion. Any unexpected breakdowns, slowdowns, or poorly operating machinery can dramatically impact production and, ultimately, the operation’s profitability.

Falk surplus parts play a critical role in keeping operations running as smoothly and as efficiently as possible. With the right Falk gearboxes and surplus gear reducers, along with a solid maintenance plan, you can keep your operation moving seamlessly despite any sudden breakdowns in equipment.

We provide the best parts and services in the industry. With 75 years of combined experience, industries across the country know they can rely on our parts as well as Rexnord Industrial Services’s nationwide network for repair, remanufacturing, and predictive maintenance services.

How Do You Maintain an Industrial Gearbox?

Taking the time to check and maintain equipment can prevent catastrophic failure during the use of industrial applications. For example, a worn gear can shut down a single machine for a few hours, but a defective gearbox can halt an entire production for days.

Some ways to prevent downtime are to perform maintenance on your Falk surplus gearboxes at regular intervals. You can do this by checking that all seals are holding and that high-wear parts are within

the manufacturer’s specified limits. If any parts are worn or defective, they can be replaced or repaired upon inspection.

After a repair or replacement on a piece of machinery is completed, keep a detailed log of maintenance cycles and which parts are replaced. This will help keep track of which replacement parts need to be ordered to maintain your spare parts inventory in case of any future malfunction.

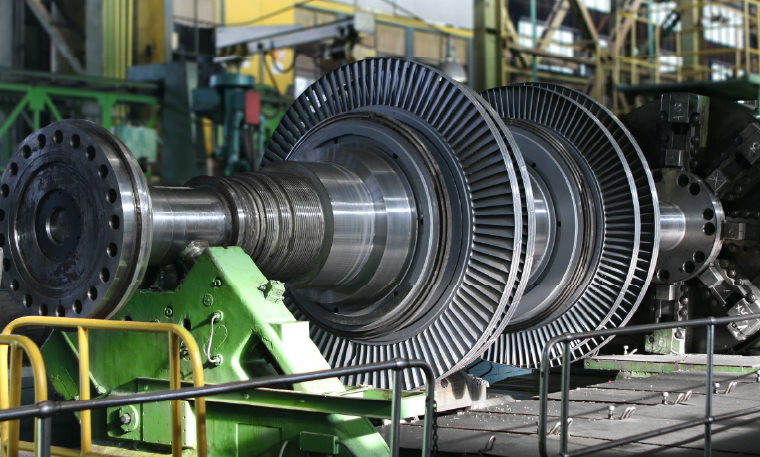

Industrial Gear Reducer Repair Services

We offer onsite Falk gear drive system repair, restoration, worn part replacement, and damaged assembly repair on all gearbox types. We can provide field analysis, drive upgrades, vibration analysis, and full load tests in addition to our standard services. Our customers can even service drive systems that the manufacturer no longer supports with our extensive inventory of used parts.

Learn more about our Falk Product Repair & Renew Services.

Should You Repair or Replace the Gear Reducer?

Many things can become defective due to long-term wear and tear, causing the performance of a gearbox to degrade. This can be due to wear of gear teeth, bearing elements, the degradation of housing bores, and seal leakage. However, many can be repaired at a fraction of the cost of buying a new one, even if the failure experienced is catastrophic.

Rather than replacing a piece of machinery, you may want to repair it. It takes a team of experienced, knowledgeable technicians, inspectors, and engineers to make complicated repairs. Our team doesn’t stop at simply returning the gearbox to its original design parameters; value added upgrades are part of all of our repairs.

Value Added Upgrades

Our clients receive the highest quality parts and repair services from industry experts, such as:

- Gearing systems made to original OEM specifications and seals replaced by original or better quality materials

- Gears and pinions made to AGMA 12 standard or better, depending on the application’s needs

- Chemically dipped housings to prevent future failures caused by debris in the lubricant

- And more!

We can also service remanufactured gear drives, assist with unit upgrades, and provide replacement units.

Service Offerings

Some of the services and repairs range from refurbished components to new components, including housings, along with a complete component inspection and evaluation.

We also perform expert failure analysis to determine performance upgrades. Our testing is no-load spin testing, and we run performance monitoring and diagnostics.

We can provide reverse engineering and coupling mounting, bearing mounting and dismounting, motor mounting, and more.

Industry Knowledge

When working with a repair or replacement service, you want to know that they will complete the project with knowledge and efficiency. This is why many diverse industries rely on Falk surplus gear reducers, gearing, and gearboxes to help them achieve peak efficiency.

Falk parts are used in industries such as:

- Mining: gearboxes are used in belt conveyors in underground mining operations, drive bucket wheels for open-pit mining, and on the cutting heads of road headers.

- Pulp and Paper: gearboxes drive paper machine dryers, web-fed printing presses, packaging machinery, and pulp processing machinery.

- Marine: gearboxes serve a critical role in driving a ship’s power systems in high-revving engines to regulate speed for the propeller.

- Oil and Gas: gearboxes are used in pumps and designed to endure extreme temperatures in frigid environments.

- Cement: gearboxes are used in material handling equipment, hydraulic roller press, crusher, blending beds, grinding rollers, vertical mills, kilns, and more.

- Energy: drivetrains for wind turbines are composed of a gearbox and a generator. The gearbox connects the turbine’s low-speed shaft with the generator’s high-speed shaft.

Industry knowledge is the cornerstone of NW Industrial Sales, LLC. So whether you’re looking for an obsolete part for your application or want to increase efficiency with a new product, we have you covered.

Falk Industrial Gearbox & Gear Reducer Suppliers

As agents of Rexnord’s Industrial Services division, we have access to a vast network of parts and product manufacturers. As a result, we can also quickly and expertly provide our clients with the industrial services they need.

We are available 24 hours, 7 days a week to connect you with an industry expert who can customize a solution to your needs. Contact us today.