The most effective tools the oil and gas industry have to reduce methane emissions are quality sealing solutions. Methane gas is one of the most potent greenhouse gases, with its heat-trapping power 20 times greater than that of carbon dioxide over a 100-year period. As natural gas production continues to grow as an important part of the energy economy, being able to have minimum leakage is a top priority that saves both the environment and prevents the loss of valuable products.

EPA Rulings On Methane Emissions

The oil and gas industry involves multiple operations and equipment to extract and refine natural gas. These include wells, natural gas gathering lines, processing facilities, storage tanks, and distribution pipelines. At each of these stages the potential for leaks exist.

In August of 2020, the EPA issued two new rules aimed to make compliance easier for the oil and gas industry. These are expected to save the industry millions of dollars in compliance costs a year. The rules help to simplify parts of the 2016 regulation and change the standards in record keeping and reporting requirements. A full breakdown can be found on the EPA’s website here.

The Role of Fluid Sealing Solutions to Prevent Emissions

Fluid sealing solutions will continue to play an important role in helping the oil and gas industry save money and conform to the EPA’s regulations. These solutions are proven and cost effective and are ready to be implemented.

A sealing solution helps prevent fugitive emissions by reducing the amount of leakage in a pipeline or a joint. Fluid sealing products are often an overlooked part of an industrial operation, and their use is often not understood completely. Each has an important role to play in the reduction of methane and other volatile emissions. The major types of sealing solutions include:

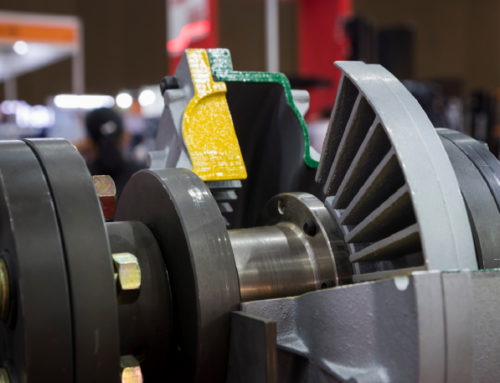

- Mechanical seals. These are used to seal a rotating shaft as it enters the housing of the centrifugal compressor. A mechanical seal prevents gases from escaping in areas where there is motion between the shaft and the housing.

- Gaskets. These are used as a static seal between two stationary components. They are used commonly on the flanges that connect piping, valves, compressors, pneumatic driven pumps, and many more kinds of equipment. The proper use of this sealing solution can lead to a great reduction of emissions due to the high volume of them in a given application.

- Compression packing. This fluid sealing solution can be used to seal valve stems and shafts of reciprocating compressors. Valves are a major source of emissions, due to their high usage, and modern high-fiber sealing helps to keep their emission levels very low.

Quality Fluid Sealing Solutions Save The Oil & Gas Industry Money

Reciprocating compressors also contribute to fugitive emissions, but these can be dramatically reduced with the application of new packing when old packing has become worn. The difference between new and old packing is dramatic, with new packing leaking 60 cubic feet an hour, and worn packing leaking up to 900 cubic feet an hour.

If you are looking for a sealing solutions distributor, look to NW Industrial Sales, LLC. We boast a robust inventory of fluid sealing solutions and have 75 combined years of experience in a variety of industries, including oil and gas, marine, grain, paper and pulp, and more.

As certified agents for Rexnord’s Industrial Services division, our clients receive expert repair and maintenance services. Rexnord’s field service technicians are known for their OEM repair expertise and predictive maintenance. We are here to meet your needs 24/7. Contact us today!