A fluid drive is a type of coupling that sends mechanical power from a motor to an output turbine. These systems, which transmit rotational power, are also known as fluid couplings, fluid clutches, and fluid flywheels.

Fluid drives are very common in vehicle transmissions, where they serve as an alternative to a mechanical clutch. Because of their benefits and longevity, these systems also have numerous hydraulic industrial applications. They play a pivotal role in myriad industries, including rail transport, aviation, marine, mining, and more.

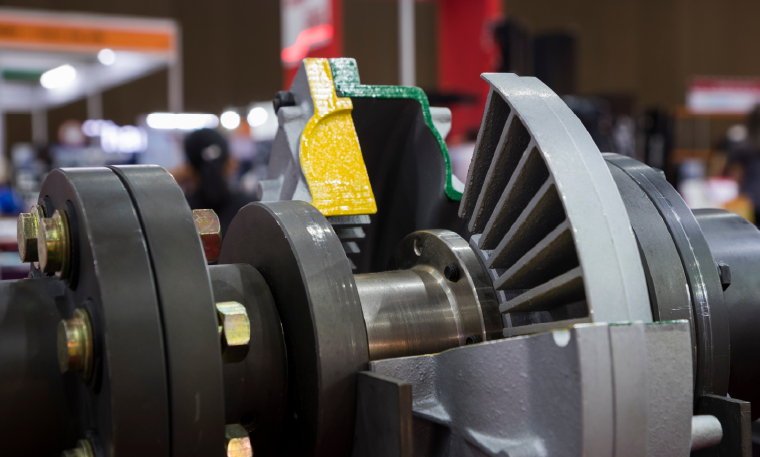

The Parts Driving Fluid Coupling Systems

A fluid drive system relies on a relatively simple design with three primary components. They include the housing (also referred to as the shell), impeller, and turbine.

The drive turbine, which connects to the engine or motor, produces an outward rotational motion. The power gets transferred to the hydraulic fluid, which, in turn, spins the output turbine. A vital feature of fluid coupling is that the parts are not in direct contact with one another.

This design is extremely useful for industrial applications because of its vibration-free operation, low-maintenance requirements, and longevity.

What Does a Fluid Drive Do?

- Smooth Power Transmission: Because there is no direct mechanical contact, power transmission is smooth, even in extreme conditions. It is free of vibration and noise, which can improve precision.

- Wear-Free Power and Longevity: The absence of a mechanical connection between the input and output elements means there is no wear from parts grinding against each other.

- Perfect for High-Inertia Starts: Fluid-driven systems offer smooth and controlled acceleration regardless of motor size. This trait makes these couplings the perfect choice for any machines requiring high inertia starts.

- Overload Protection: Fluid drive units can balance loads across multiple systems because one coupling can temporarily operate at a 100% slip. Even in these situations, they protect against motor overloads by limiting maximum torque.

- Adjustable Torque: In fluid drive systems, the maximum torque can be adjusted by varying the amount of fluid in the casing. This feature allows you to set the correct amount of torque for your needs. In addition to ensuring the right amount of power for your processes, these adjustments can improve efficiency.

Fluid couplings have multiple advantages, from providing controlled soft start ups to helping prevent shock loads.

The Industries Powered by Fluid Couplings

Fluid drive systems have a wide range of industrial applications, especially for equipment involving continuous cyclic loading or high inertia starts.

Industries include:

- Rail Transport: Fluid couplings help power diesel locomotives.

- Aviation: Used as barometrically controlled hydraulic clutches for centrifugal compressors.

- Marine: Used in a variety of propulsion units to reduce vibrations.

- Mining: Couplings can stall conveyor crushers in the event of mechanical issues, thus improving safety.

Fluid drive systems and fluid couplings have many benefits that have made them popular across a variety of industries.

The Source for All Your Fluid Drive System Needs

NW Industrial Sales offers a wide range of quality fluid drive systems and fluid sealing solutions, including metal and rubber seals, gaskets, and replacement parts. Our vast inventory also includes gearboxes, mixer drives, backstops, OEM, and obsolete parts.

Contact NW Industrial Sales if you have questions or would like to learn more about our fluid drive offerings.