Disruptions in the international supply chain have been some of the biggest challenges posed by the COVID-19 pandemic. Regardless of your industry, gearbox supply chain market disruptions can negatively impact your company.

When a critical piece of machinery in your factory or warehouse cannot operate due to a missing part, it will eventually impact relationships with your customers. In the end, people aren’t concerned about the inner workings of your manufacturing line—they just want to receive their orders on time.

Gearbox Supply Chain Disruptions & COVID-19

Notable industries impacted by supply chain shortages during the pandemic include:

- Pulp and paper

- Marine

- Chemical refineries

- Mining

- Oil and gas

- Energy

Supply chain disruptions were even more difficult for manufacturers that had been sourcing lower-cost parts from China. As the global economy ground to a halt with the pandemic, so did manufacturers shipping surplus gearboxes from Asia.

So, how can you protect your company from supply chain volatility? Our experts share tips and best practices.

Be Better Prepared for Emergencies

Be Better Prepared for Emergencies

While it is going to take a long time for supply chains to normalize, there are some key lessons to be learned from the pandemic. The smartest course of action for industries is to prepare for potential challenges.

A great starting point in preparing for emergencies is to audit your current supply chain for visibility and weaknesses. If you are unable to map parts procurement for your entire manufacturing line, you leave your business open to risk.

It’s also advisable to consider how supply chain shortages might impact relationships with your customers. Due to unknowns in the global economy, supply chain forecasting should always veer toward the conservative side. In such situations, under promising and over delivering is always a smart course of action.

Invest in Spare Parts Management

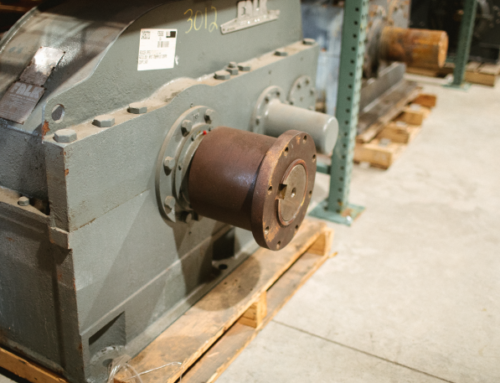

The best way to prepare for supply chain shortages is to have a surplus of Falk gearbox parts on hand at all times.

In order to procure surplus gearboxes, you must reassess your parts budget to allocate more money for a larger inventory. While this will cost you more upfront, you are investing in the stability of your company—while also protecting relationships with your most valuable customers.

At NW Industrial Sales, LLC we specialize in locating discontinued OEM and hard-to-find parts. In industries as diverse as green energy and mining, we can find products and parts to fit any industrial application.

Falk Gearbox Motor Suppliers & Repair Experts

With such glaring weaknesses in supply chains, the best way to protect your business is to partner with qualified Falk gearbox distributors.

NW Industrial Sales has a massive inventory of surplus gearboxes, obsolete components, and OEM parts on hand at all times.

Since we are agents of Rexnord’s Industrial Services division, we are part of a nationwide network for repair, remanufacturing, and predictive maintenance services. Not only will we keep you supplied with parts, but will also help you maintain and fix critical components in your manufacturing line.

Contact us today to learn more!

Be Better Prepared for Emergencies

Be Better Prepared for Emergencies