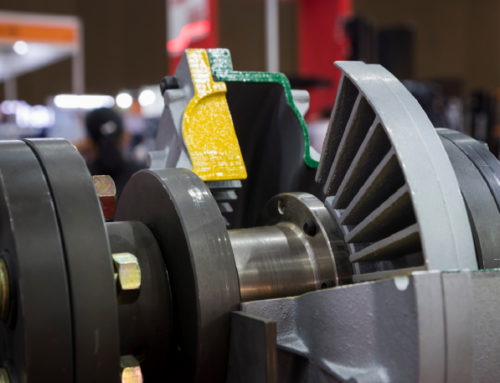

Fluid drive systems allow engines and motors to transmit rotational power. Because it relies on liquid to transmit mechanical energy, the system protects against issues related to starting and speed changes in machinery and equipment. This design is also known as fluid coupling because liquid joins the two mechanical components.

When traditional machinery starts, stops, or changes speed, the sudden movement can cause parts to snap, bend, become misaligned, or wear down over time. Because liquid transmits energy from the power source to the output turbine, it does not create the same type of shock that two solid mechanical components would. This makes it invaluable for the performance and longevity of industrial equipment.

NW Industrial Sales, LLC brings a combined 75 years of experience with fluid power and the sealing solutions that are necessary to ensure high-level performance in industrial settings. This knowledge and eye for quality make our team the best option for sealing solutions in the Pacific Northwest.

Product Advantages You Can Count On

1) Long-lasting components

If you have a coupling system where liquid transmits torque between a power source and an output turbine, there is less wear. If your machine transmits power between two gears, the teeth of these components will eventually wear down. The fluid acts as a cushion between the two mechanical components, so it does not cause the same wear and tear. This limits parts replacement and the cost associated with materials, labor, and the stoppage of operations.

2) Safety benefits

Liquid-powered systems do not create the same level of heat or sparks, making them ideal for environments with flammable materials. Also, this power option does not carry the same risk of electrocution or fire that can come from an electric motor. The right fluid sealing products can increase workplace safety even more.

3) Useful in challenging environments

Fluid drive systems are the best option for many marine applications. Unlike electrical motors, which cannot be submerged unless fully sealed, liquid-based power can work safely and effectively underwater. As long as the design includes quality seals and gaskets, it will function as well submerged as it does on dry land.

4) Accommodate sudden speed changes

Since liquid is not rigid, it responds more gradually to speed changes. It does not start abruptly, so there are no concerns about stalling motors or bending and snapping parts. You also avoid shuddering or clanking, which could throw off precision processes.

5) Straightforward maintenance

The liquid in this type of industrial design transmits power, and it also lubricates and cools the other mechanical parts. It needs to be clean and stable to do this. Maintenance for these systems is often as simple as changing the fluid (just as you would change the oil in your car).

If you work with an expert like NW Industrial Sales, LLC, you will have access to a nationwide network of technicians who can handle the job easily. They can also inspect the fluid sealing, gaskets, and other components to ensure the entire system can function safely and efficiently.

Quality Fluid Sealing Products for Any Industrial Application

In addition to a quality fluid drive system, you need to ensure that all parts, from the turbines to individual fasteners, seals, and gaskets, will stand up to rigorous use. With extensive experience with drive systems, expertise in fluid sealing and engineering, quality components, and a nationwide maintenance network, NW Industrial Sales, LLC is the ideal source for all your fluid drive system needs.

Contact NW Industrial Sales, LLC to learn what solutions we can offer you.