If your organization experiences gearbox failure, an immediate solution is required to prevent financial losses and other adverse outcomes. We strongly recommend having a trustworthy Falk technician on speed dial. Doing so may ensure your supply chain runs smoothly and may prevent expensive manufacturing shutdowns.

We also encourage folks managing that equipment to increase their awareness of the general maintenance of a gearbox.

What is the General Maintenance of a Gearbox?

The general maintenance of a speed reducer depends on its use and environment. Regardless, every organization should examine or perform preventative routine maintenance to support the longevity of a Falk speed reducer.

Still, we understand if you ask yourself, “How is preventive maintenance on gearboxes performed?” Answering that question depends on your experience or if you’re working with a professional Falk technician.

We’ve curated our advice to offer value for new and experienced gearbox users alike.

1) Clean Your Environment & the Gearbox

Gearboxes become exposed to contaminants like dust, moisture, oils, and other hard particles. Remember, those contaminants can harm the gearing itself or degrade the lubricant.

Cleaning your workspace and a gearbox’s work environment is the easiest way to prevent harmful contaminants from reaching a speed reducer. Using the proper cleaning products, brushes, and degreasers on the machinery will also extend the life of the parts.

2) Reduce Stressors

Stress on a gearbox can result in increased friction and energy losses. Reducing gearbox stress can contribute to improved energy efficiency by minimizing issues. This is particularly important in applications where energy consumption is a critical consideration.

Tips for Reducing Gearbox Stress:

- Distribute loads evenly among the gears to prevent excessive stress on its components.

- Ensure gearbox components are correctly aligned.

- Confirm that your gearbox operates within the manufacturer’s mechanical and thermal ratings advice.

- Provide effective cooling for the gearbox to prevent overheating.

- Use dampening devices or other means to absorb excessive vibrations.

- Avoid sudden starts or stops.

- Properly lubricate your Falk gearbox.

3) Use the Correct Lubricants

Follow the manufacturer’s guidance concerning the type, grade, and quantity of lubrication related to your gear reducer. Renew the lubricant regularly to avoid bearing fatigue, improve efficiency, and increase the longevity of your speed reducer.

We encourage you to contact our Falk gearbox repair service team if you need advice on which lubricant pairs best.

4) Assess & Replace Couplings

The couplings are crucial for maintaining proper alignment and ensuring optimal power transmission between the gearbox and the drive shaft. If they fail the eye test or appear damaged, it’s time for replacements.

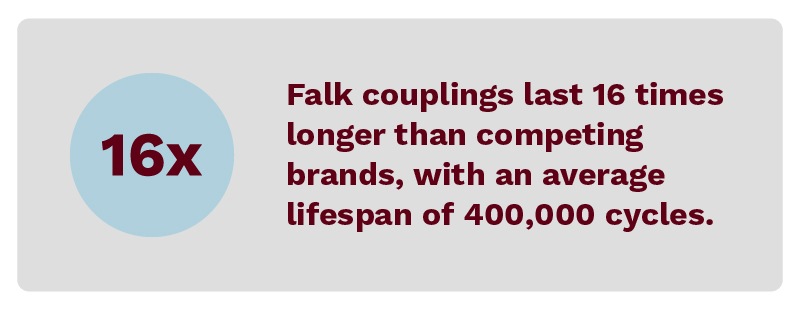

For those who need a recommendation, we use Falk couplings because they offer the following benefits:

- 16 times more durable in impact-loading applications

- Last 16 times longer than competing brands, with an average lifespan of 400,000 cycles

- 87.5% more durable than other brands

If you need additional assistance assessing or changing your couplings, we invite you to contact a Falk technician for help.

5) Assess Torque Control

Gear drives are the most reliable method of changing the shaft speed from a constant power source. They can also increase the torque for variable speed for added control.

We recommend ensuring the motor’s power and speed align with the manufacturer’s advice concerning load limits and torque guidance to avoid overloading. We also advise leaving those adjustments to a professional technician if your gearbox experienced overloading from abrupt changes or excessive loads.

6) Replace Damaged Parts

A wide variety of industries use gearboxes by Falk for the most rigorous industrial applications. While they are the most resilient and durable speed reducers on the market, replacing or repairing damaged parts is essential to keeping any job moving.

We offer a vast inventory of new and used Falk parts. If you can’t find the part you need, we invite you to contact us to have us search for what you need on your behalf.

Connect with a Falk Gearbox Technician

The recommendations above may require varying skill levels. Therefore, it’s best to partner with a professional gearbox repair and renewal specialist to avoid additional issues. Remember, we’re here when you need us.

As agents of Rexnord’s Industrial Services division, we have access to a nationwide network for repair, remanufacturing, and predictive maintenance services. We encourage you to seek more gearbox advice by calling us at 503-468-0454 or contacting us directly.