Gearboxes play a vital role in everything from your car’s transmission to supporting industrial equipment that drives factories, mines, and the power industry. While the machine is frequently referred to simply as a box, the bearings housed within play a crucial role in ensuring your application operates efficiently, reliably, and successfully.

How Bearings Support Gear Reducers

If you’ve ever wondered what makes a gearbox run smoothly, the answer is the bearings. A manufacturer like Falk only uses high-quality Tier 1 bearings to ensure world-class performance and longevity. These parts support the rotation of the shafts in a motor, securing the shaft to ensure efficiency and reduce heat generation, mitigating the potential for damage.

Depending on the application, speed reducers may use different types of bearings, from classic ball bearings to roller bearings and even those with specialized designs.

The most common bearing types found in Falk gear reducers include:

- Cylindrical roller bearings

- Needle bearings

- Plain bearings

- Spherical roller bearings

- Tapered roller bearings

- And thrust bearings

Every speed reducer Falk manufactures uses bearings based on the configuration to support precision. They’re also engineered to handle specific load conditions and operating environments, ensuring reliable performance even in the most demanding conditions.

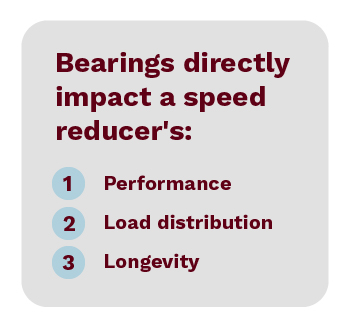

Do Bearings Impact Gearbox Performance?

Yes. Falk engineers design every gearbox with designated service factors, loads, and duties in mind. What’s more, the bearings directly impact a speed reducer’s performance, load distribution, and longevity, which is why we emphasize the importance of using the correct parts to avoid expensive failures.

- Reduced friction for smoother rotational movement

- Preventing excessive wear and tear

- Increased energy efficiency

- Improved power transmission with minimal resistance

- Lower noise and vibration levels

- Decreased heat generation for added protection

Remember, bearings act as a smooth interface between the rotating components in a gearbox, allowing them to spin with minimal resistance. Additionally, bearings do more than reduce friction—they also help distribute the immense loads placed on the gear drive.

Meaning that without them, the gears and shafts would grind against each other, leading to potential catastrophic failure.

What Happens if Gearbox Bearings Fail?

If you need to replace a gear drive’s bearings and feel uncomfortable making a decision, we recommend contacting a dependable Falk repair technician to avoid damaging equipment.

6 Tips for Protecting Gear Drive Bearings

By following the preventive maintenance practices curated by our Falk speed reducer repair and renewal specialists, you can help extend the service life of the gear drive bearings and minimize the risk of premature failure or unexpected downtime.

1) Proper Lubrication: Use the recommended lubricant type, grade, and quantity specified by the manufacturer.

2) Contamination Control: Keep the gearbox and the surrounding area clean to prevent ingress of dirt, dust, and other contaminants.

3) Alignment and Mounting: Ensure proper alignment of the gearbox with the connected equipment (e.g., motors, pumps) to avoid excessive bearing loads.

4) Operating Conditions: Avoid overloading the gearbox beyond its rated capacity, as excessive loads can lead to premature bearing failure and other issues, including brinelling, spalling, and fretting.

5) Regular Inspections and Professional Maintenance: Implement a regular inspection schedule to check for signs of bearing wear, such as increased noise, vibration, or temperature.

6) Proper Storage and Handling: If the gearbox is not used for an extended period, review our storage advice to prevent bearing damage such as corrosion or lubricant degradation.

Falk Speed Reducer Suppliers & Expert Repair & Renewal Specialists

As a member of Rexnord’s Industrial Services division, we offer an extensive gear reducer and parts inventory as well as a comprehensive range of gearbox maintenance, repair, and remanufacturing solutions.

We invite you to explore our support further by giving us a call at 503-468-0454 or by contacting us online. Our knowledgeable team is ready to assist you 24/7.