Industrial businesses face considerable challenges on any job site. One such concern is ensuring that the equipment and gearbox supporting it can withstand the demanding conditions and environments of the work they perform while maximizing efficiency.

Improving a gearbox’s efficiency and performance requires a holistic approach tailored to a specific application. This includes a mixture of steps more experienced folks can do independently and others we recommend leaving to your professional Falk technician.

No matter the route you take, here’s how our gearbox motor supplier team extends the lifespan of a speed reducer while elevating efficiency.

Use the Correct Gearbox for Your Application

Falk manufactures several gearboxes in different configurations, sizes, specs, and angles. Remember, your gearbox efficiency directly impacts energy consumption and operating costs, which is why we use Falk.

- A gearbox’s operating speed and torque

- Its efficiency and power

- Its load-carrying capacity

- Its environmental factors

- Its precision and control

- And its mount and spacial needs

We know finding the right gearbox can be challenging. Therefore, we invite you to speak with a Falk technician directly to find the speed reducer that matches your needs.

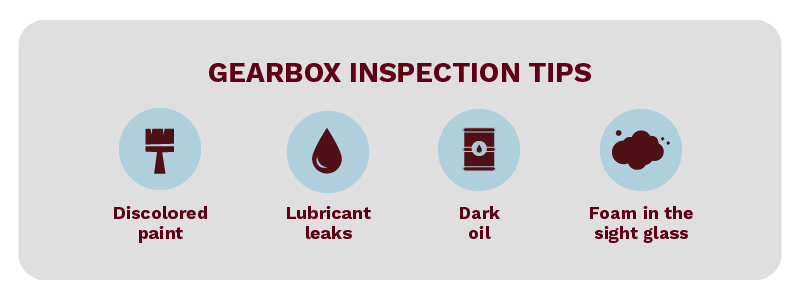

Inspect the Gearbox

Monitoring for signs of wear is one of the best ways of improving gearbox efficiency and performance. Keeping your work areas clean is also essential to avoiding particle contamination that could cause damage.

Any damaged parts should be replaced immediately using the surplus gearbox parts you may have on hand. Nevertheless, here’s a few inspection tips to keep you in the right gear:

- Look for signs of overheating, such as discolored paint, water, dark oil, or foam in the sight glass and sudden temperature changes.

- Monitor for gear wear, such as brinelling, spalling, and misalignment.

- Assess the unit for contamination and oil or lubricant leaks.

- Perform a vibration test to confirm that you’re not experiencing any change in internal function or operating at abnormal noise levels.

Prioritize Regular Preventive & Professional Maintenance

No matter how well you maintain your industrial equipment, industrial gear drives inevitably require professional care. Remember, gear drives are subjected to immense stress and wear over time, making it essential to have them serviced by experts who can diagnose and address any potential issues before it’s too late. Remember that neglecting timely maintenance can lead to costly breakdowns, compromising productivity and safety within your facility. That’s why it’s important to have a Falk technician on speed dial.

Check Your Oil

Proper lubrication and oil maintenance keep your gear drive’s temperature as cool as possible. This prevents friction and keeps contaminants away from gear drive components, allowing your Falk speed reducer to run more efficiently.

We recommend checking to ensure the lubricant matches the manufacturer’s specifications. Assuming it does, you’ll then want to run an oil analysis that checks for the following:

- Water

- Sediment

- ISO Rating

- Viscosity

- Acid Number

- And other particles or contaminants

Avoid Overloading & Overhung Loads

Operating a gearbox beyond its rated load capacity can damage it. We call this an excess load. Motor power and speed determine the torque limit, so changes to either factor can impact gearbox performance.

Belts, chains, flywheels, rigid couplings, and other devices mounted on the input shaft also create overhung loads. If they exceed the gearbox’s overhung load limit, the shaft and bearings could be damaged.

In either case, avoiding either situation by knowing your gearbox’s service factor will ultimately improve performance and gearbox reliability. Review your service factor and know it to get the most out of your gearing.

Rely on Our Gearbox Motor Suppliers to Reach Peak Performance

Ensuring optimal gearbox performance maximizes efficiency and minimizes downtime. Our team of experienced Falk technicians offers comprehensive gearbox repair and maintenance services tailored to your application and needs.

From proper lubrication and alignment to load balancing and component replacement, we employ industry best practices to extend the lifespan of your gearboxes. Contact us today for a personalized solution to your gearbox needs.