We know mechanical managers and engineers are crucial to any industrial operation. Their contributions significantly enhance productivity and efficiency, ultimately boosting profits beyond the bottom line. Whether you work in oil and gas, mining, or another industry relying on heavy machinery, these eight tips were curated by our Falk repair team to help those seeking gearbox replacement advice.

1) Recognize Gearbox Fatigue

Regular inspections and vibration analysis can expose mechanical issues before they escalate. As Falk technicians, we recommend keeping an eye (and ear) out for the following signs indicating that it might be time for a gearbox upgrade:

- Unusual noises: Grinding, whining, or clicking sounds

- Excessive vibration

- Oil leaks or contamination

- Increased operating temperatures

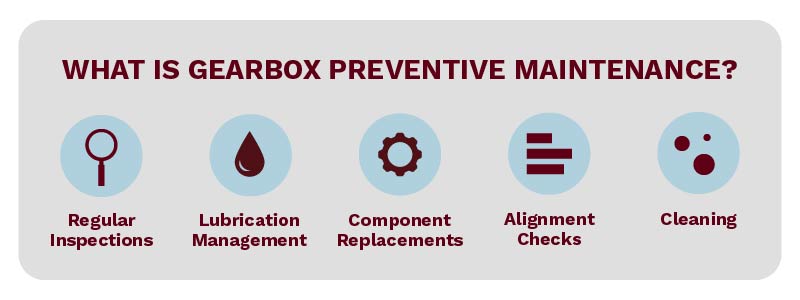

2) Prioritize Preventive Maintenance

Your next gearbox should deliver the resilience and dependability that’s on par with a brand like Falk. For example, your maintenance schedule should generally include:

- Regular oil analysis and changes

- Bearing inspections and lubrication

- Seal checks and replacements

- Alignment verification

If routine or preventive maintenance on an old gearbox becomes time consuming, we recommend partnering with a professional Falk repair team to receive support tailored to your operational needs. Doing so will help you determine whether you need a new gearbox outright or need more robust repairs.

3) Train Your Team for Optimal Gearbox Management

Your maintenance team is your first line of defense against gearbox failures. Training a gearbox maintenance team is crucial to ensure they can effectively identify and address potential issues, minimizing downtime and prolonging the lifespan of the equipment.

This can be achieved through:

- Providing regular training on gearbox maintenance best practices

- Ensuring they’re familiar with the specific models in use (e.g. Falk gearboxes)

- Encouraging participation in industry seminars and workshops

4) Invest in Durable Falk Gearboxes

When it’s time for a replacement, resist the temptation to cut corners. Investing in high-quality gearboxes such as Falk yields significant long-term benefits, such as:

- Superior durability in harsh environments

- Higher efficiency ratings, leading to energy and cost savings

- Exceptional performance across various applications

- Comprehensive aftermarket support

5) Pick a Gearbox With Smart Capabilities

If your gearbox equipment can’t keep up with smart manufacturing standards, it’s time to upgrade. In today’s digital age, data is your ally. Your next gearbox should be able to sync with systems to:

- Track gearbox performance metrics over time

- Analyze failure patterns to inform preventive maintenance strategies

- Reduce downtime and streamline production

6) Keep Surplus Gear Reducers On Hand

6) Keep Surplus Gear Reducers On Hand

Working with a reputable surplus gearbox supplier and repair vendor like NW Industrial Sales, LLC offers numerous advantages, including:

- Minimize the frequency of inventory replenishment, optimizing stock levels

- Enhance your ability to predict and plan for future needs accurately

- Achieve a more reliable and stable supply chain for your industrial operations

By partnering with a supplier that has a large inventory of reducers and parts, you can be confident that your industrial application needs will always be met.

7) Upgrade if You’re Overloading a Gearbox

Mechanical managers often need to choose between balancing productivity with equipment longevity. Unfortunately, making the wrong decision can overload your gearbox, leading to premature failure and expensive downtime.

Signs of Overloading

- Excessive heat generation

- Unusual wear patterns on gears and bearings

- Frequent oil degradation

- Unexplained increases in power consumption

If you can’t change the processes a gearbox supports, upgrading your speed reducers to align with your applications is the most cost-effective measure. Start by knowing your gearbox’s service factor and operational limits. When assessing load requirements, factor in safety margins. Then, consider both continuous and peak load scenarios.

Once you have that information, you can invest in new or refurbished Falk parts or partner with a technician to help you select the right solutions.

8) Partner With a Trusted Gearbox Supplier

Don’t go it alone. Establish relationships with gearbox specialists who can provide:

- Expert advice on gearbox selection and replacement

- Specialized repair services for complex issues

- Access to a wide range of parts and complete gearbox units

Falk Gearbox Supplier Offering Repair & Renewal Services

At NW Industrial Sales LLC., we pride ourselves on being your trusted partner nationally. We invite you to begin a partnership with us by contacting us at your convenience.

6) Keep Surplus Gear Reducers On Hand

6) Keep Surplus Gear Reducers On Hand